HDPE CNC machining

HDC for HDPE CNC machining

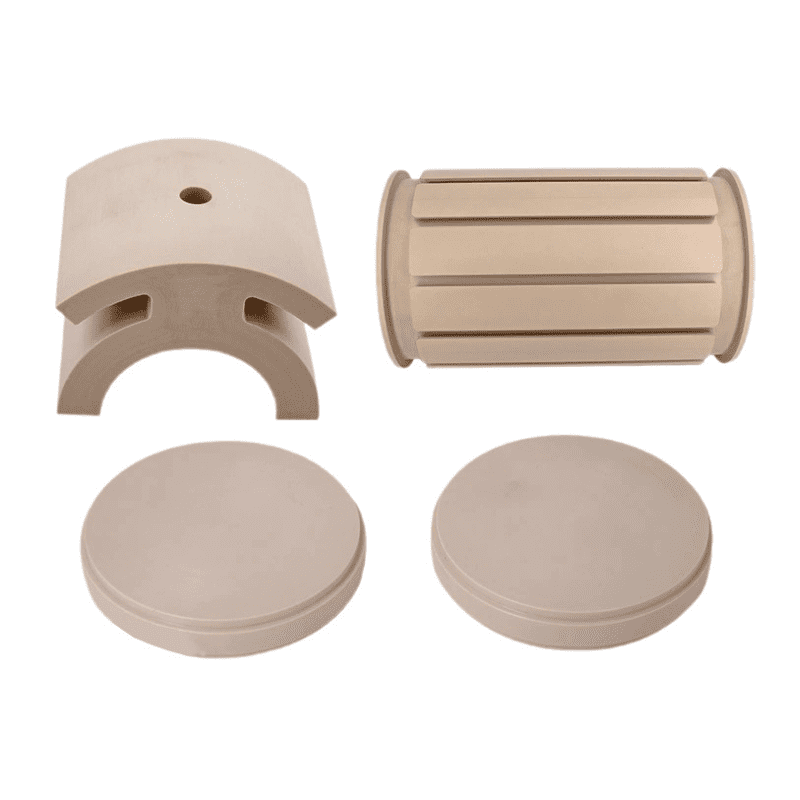

High-Density Polyethylene which is commonly known as HDPE is an amazing plastic for machining applications. Some of the common parts made from HDPE CNC machining are electrical parts, automotive parts, construction parts, etc. HDPE is largely resistant to chemical and thermal changes and offers a very good strength-to-weight ratio. Here is why you should choose us for your HDPE machining needs.

Why Choose Us

High precision machining of HDPE

We have high precision machining tools at our disposal like the 5-axis CNC machines and Swiss CNC machines. Therefore, our HDPE products are made with precision and fulfill the tolerance limits required by our clients. You will benefit from our state of the art machines and the high level of accuracy that you will get in your HDPE parts.

We offer custom designing option for HDPE parts

Prototyping of HDPE parts is our expertise. We have separate design team that has the latest CAD/CAM software for development of designs. You can either share the blueprint of the custom part or share your requirements with our design team. After getting your requirements, we will develop high quality HDPE parts for you. Therefore, you will get your custom design and also can check it as a sample before batch production.

Great customer support

Nothing is more important to us than a satisfied client. Therefore, we have a post-sales customer support section that deals with our client’s queries and questions. So, our lines of communication are always open for our clients to share their feedback with us and we will help them out if they have any issue with the parts.

Most competent rates

We understand that no matter how good the engineering and design of a product is, as long as the rates are not competitive it is not viable for business. Therefore, we have a dedicated team that researches on applying the least cost models for production of HDPE machined parts. As a result, you get the most competitive rates for HDPE parts with us.

Available materials

HDPE is available in two grades, namely, 300 and 500 grades. Main difference between the two grades is of density. Generally, HDPE has a density ranging from 0.955 g/cm3 to 0.961 g/cm3. The tensile strength at yield is 23 to 29.5 MPa. Due to the high chemical resistance, HDPE machining parts are used extensively in the medical and food packaging industry. It not only keeps the food items fresh, it also does not allow bacteria and other organisms to grow on the HDPE parts.

FAQ

Is HDPE a good option for CNC machining?

Yes. HDPE is ideal for machining parts as it offers low resistance to tools and is resistant to temperature over a long range. Furthermore, the material holds firmly during the machining process, therefore, the tolerances are developed very precisely as per the requirement of the clients.

What are main applications of CNC Machined HDPE parts?

HDPE machining of parts is a very common practice around the world. There are food type HDPE materials and non-food type. The food type material is majorly used in the food packaging industry like bowls, boxes, packing, etc. Whereas, the non-food type HDPE is majorly used in electrical connections, packaging, connectors, automotive parts, etc.

Is HDPE machining a price effective solution?

Yes. HDPE is one of the most economical materials to use for a large number of applications. Even in comparison to a lot of metal and its alloys, HDPE machining is a much more economical and cost-effective solution. Furthermore, the cost of reworking, due to damages to the material, is very minimal when machining HDPE so it is an ideal choice for machining.

[toc]