Nylon CNC Machining Service

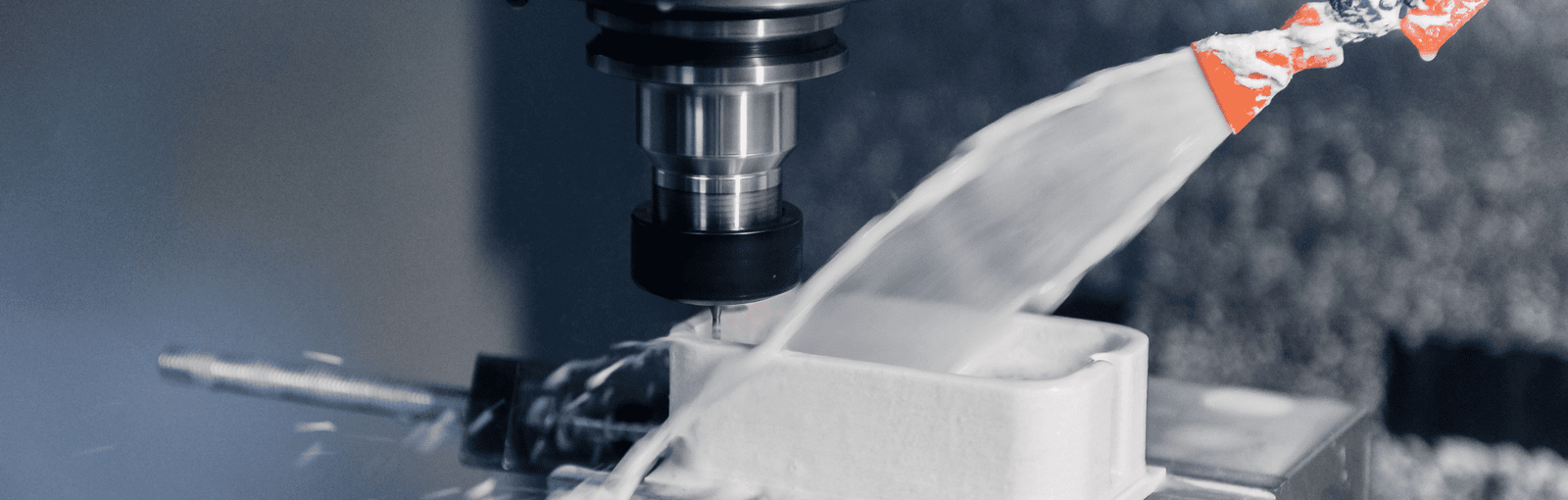

HDC is a company based in China that has established a reputation as a leading expert in the field of Nylon CNC Machining services.

The company is committed to providing its clients with precision-engineered Nylon parts using state-of-the-art equipment and cutting-edge technology. With a team of highly skilled and experienced professionals who possess a wealth of industry knowledge, HDC is dedicated to meeting the unique needs of each customer and delivering tailor-made solutions that exceed expectations.

From start to finish, HDC is committed to providing an exceptional level of service that is second to none, ensuring that your project is completed to the highest standards, on time and on budget.

HDC for Nylon CNC Machining Service

Polyamide or Nylon is a thermoplastic that can be easily machined into various industrially usable products. The main characteristics of Nylon include good mechanical resistance, high electrical and thermal resistance, high impact strength, and high resistance to abrasion. In addition, Nylon is lightweight, has high tensile strength, and offers has low friction. To sum it all up, Nylon is a wonderful material for use in various industrial and domestic applications. Here is why you should choose us for Nylon CNC machining.

Why Choose Us

Custom Design Option

Prototyping of Nylon CNC milling is one of our expertise. With the help of the latest CAD/CAM tools, we are able to develop custom Nylon CNC designs that you will be able to use. Furthermore, our expert team of designers will produce a part that will fulfill all the regulations and standards required for your custom Nylon part.

High Precision Nylon CNC Parts

We have state-of-the-art machining tools that can develop the most complicated and intricate Nylon CNC milling designs. You will just have to share the parameters and tolerance levels of your part. And no matter how complicated it is, we will develop it to a high precision level. Therefore, you will get Nylon parts that will be machined to the highest level of precision.

Delivery within the agreed time

Since our team of experts is working closely on delivering the parts on time, we ensure that none of the processes are overrun from the agreed time. Therefore, you will get the parts not only in the agreed time but also in the shortest time possible in the industry.

Most Competitive Rates in Market

One of the biggest advantages that you will have in working with us is that we offer the most competitive rates for Nylon CNC machining. This is not only a claim, rather, but we also have a dedicated research and development team that is working round the clock to ensure that the parts we machine are completed in the most economical manner. Therefore, you will get the most competitive rates in the market from us.

Available materials

There are many variants of Nylon, for instance, Nylon 6, Nylon 6/6, and 30% Glass-filled Nylon are the most commonly used Nylon grades. Each of these grades has its own unique characteristics that make them ideal for different applications. For instance, Nylon CNC milling parts are extensively used in Cogwheels, dampers, machining jigs, electrical insulation parts, connectors, etc.

FAQ

1、What is the tolerance of nylon in machining?

Nylon parts can be manufactured within tolerances of +/- 0.002. Due to its excellent durability and load bearing capacity, nylon is widely used in applications such as rollers. Many drums are equipped with bearings at both ends to enhance rolling efficiency.

2、Can you turn nylon on a lathe?

Turning – Turning methods for cast nylon materials should be similar to those for materials that are easy to cut, using high-speed surface speeds between 600 and 900 ft/min for roughing at a feed of 0.004 inches to 0.010 inches per revolution, and for smaller diameters, a feed of 0.003 inches to 0.007 inches per revolution may be used.

3、What are the machine parts of nylon?

Common nylon parts cover bearings, wear gaskets, washers, bushings, sprockets, tubing and more. Nylon is extremely machinable and is available in a variety of grades.

4、What is the best grade of nylon?

For lightweight engineering plastics used in high-impact and stress environments, nylon 6 is recommended, and is more visually appealing than nylon 66 because of its glossy surface and easier dyeing. It is considered ideal for automotive, industrial and military applications.

5、What are the different types of nylon for machining?

Nylon 6 (PA6)、Nylon 66 (PA66)、Nylon 6/6 (PA6/6)、Nylon 12 (PA12)、Nylon 4/6 (PA4/6)、Nylon MD (Molybdenum Disulfide Filled Nylon)、Nylon GF (Glass Fiber Filled Nylon)、Nylon HS (Heat Stabilized Nylon)

6、What tools are used to process nylon?

Cutting tools can often be manufactured from high speed tool steel for turning nylon casting materials. Carbide tools can be used for long cycle times when the tool edge remains sharp.

7、Does nylon have good machinability?

Because of its inherent strength, toughness and dimensional stability, nylon excels in machining and is able to achieve smaller tolerances. As a result, there is not much difference compared to machining metals.

8、How do you cut threads in nylon?

Cutting nylon threads is essentially similar to cutting metal threads; single point threading tools or taps can be used for external and internal threads, while molds are used for external threads. When machining nylon threads, it is recommended to use British Standard Series or American Standard Unified Threads (with rounded roots).

9、Can Nylon be machined?

Yes. Nylon can be machined. In fact, the Nylon 6/6 is ideal for machining as it is very resistant to chemical and heat changes. Also, the Nylon 6/6 is very tough against loads, therefore, is an ideal choice for machining.

10、What are the major applications of CNC Nylon Machining?

There are multiple applications of Nylon machined parts including manufacturing of gears, cogs, medical equipment, electrical insulation parts, connectors, etc.

11、What is the difference between Nylon Grades?

Each of the three is a different grade of Nylon that have different physical properties. For instance, Nylon 6 and Nylon 6/6 have a tensile strength at a yield of 10,000 psi, whereas, the Nylon 30% glass filled has of 12,000 psi. Similarly, each of the grades has different temperature ranges over which they remain in usable form. The Nylon 6/6 can operate from 90 – 215 °C, whereas, this range is slightly lower for Nylon 6. However, the Nylon 30% Glass Filled has a very high-temperature resistance ranging up to almost 250 °C.

12、Does HDC help in selecting the right material?

Yes. HDC will help you in selecting the ideal Nylon material for the CNC machining based on the specifications and requirements of your product.

[toc]