CNC Rapid Prototyping: Precision and Speed in Manufacturing

Explore how CNC rapid prototyping enhances manufacturing precision and speed. Learn about its advantages, steps, costs, and applications across various industries like medical, aerospace, and automotive.

What is rapid prototyping?

When we say “rapid prototyping”, it is a procedure that will let you produce a part rapidly and examine the capability and the possibility of error prior to ultimate fabrication. It can also be completed using different practices like CAD, 3D printing, CNC machining, etc.

CNC Rapid Prototyping is a well-known method (also known as CNC RP), it is liked by many because of its high accuracy, dimensional steadiness, and dependable features. However, only experts can manage it perfectly as it has meticulous processes.

Is CNC machining rapid prototyping?

In the world of manufacturing, there are a variety of ways to create prototypes. Perhaps the most well-known method is rapid prototyping, which uses additive manufacturing processes to create three-dimensional models from CAD files. CNC machining is another popular method, which involves using computer-controlled tools to shape materials into the desired form. So, is CNC machining rapid prototyping? In short, yes. CNC machining can be used to create prototypes quickly and efficiently. However, it is important to note that not all CNC machined parts are considered rapid prototypes. In order for a part to be considered a rapid prototype, it must meet certain criteria, such as being made from a rapid prototype machine. As such, CNC machining is a rapid prototyping technique that can be used to create high-quality prototypes in a timely manner.

What are the 3 types of prototyping?

Prototyping is an important step in the product development process. It allows companies to test out new ideas and get feedback from potential customers. There are three main types of prototyping: rapid, functional, and aesthetic. Rapid prototyping is the quickest and most cost-effective method. It involves creating a basic prototype that can be used to gather feedback and make improvements. Functional prototypes are more complex, and they are designed to test how well a product works. Aesthetic prototypes focus on the look and feel of a product. They are often used in the early stages of product development to get an idea of how consumers will react to the design. Regardless of the type of prototyping, it is a valuable tool that can help to improve the chances of success for any new product.

What are the 4 classifications of prototype?

There are four main classification of prototypes: rapid prototyping, functional, throwaway, and evolutionary. Rapid prototyping is used to quickly produce a working model of a new product or service. Functional prototypes are used to test specific functions or features of a design. Throwaway prototypes are created with the intention of being discarded after use; they are often used in Market Research. Evolutionary prototypes are developed iteratively, with each successive version incorporating feedback from users. Ultimately, the goal is to create a prototype that closely resembles the final product. The type of prototype will be determined by the needs of the project.

Why should you choose CNC machining in rapid prototyping?

Many industries are benefiting from CNC rapid prototyping, especially those that demand preciseness and particular feature. Putting money into prototype exercises with CNC machining lessens the possibility of time wasting and significant errors.

Computer Numerical Control machining is a practical choice for the lesser volume fabrication scheme. It may also be an outstanding option for it gets rid of the demand for beforehand tooling and casting because of its advantageous manufacturing technique.

What are the Pros and Advantages when using CNC for rapid prototyping?

- Repeatability- CNC machines are a computer-controlled fabricating procedure. Therefore, the moment you programmed the features, you can make countless identical components.

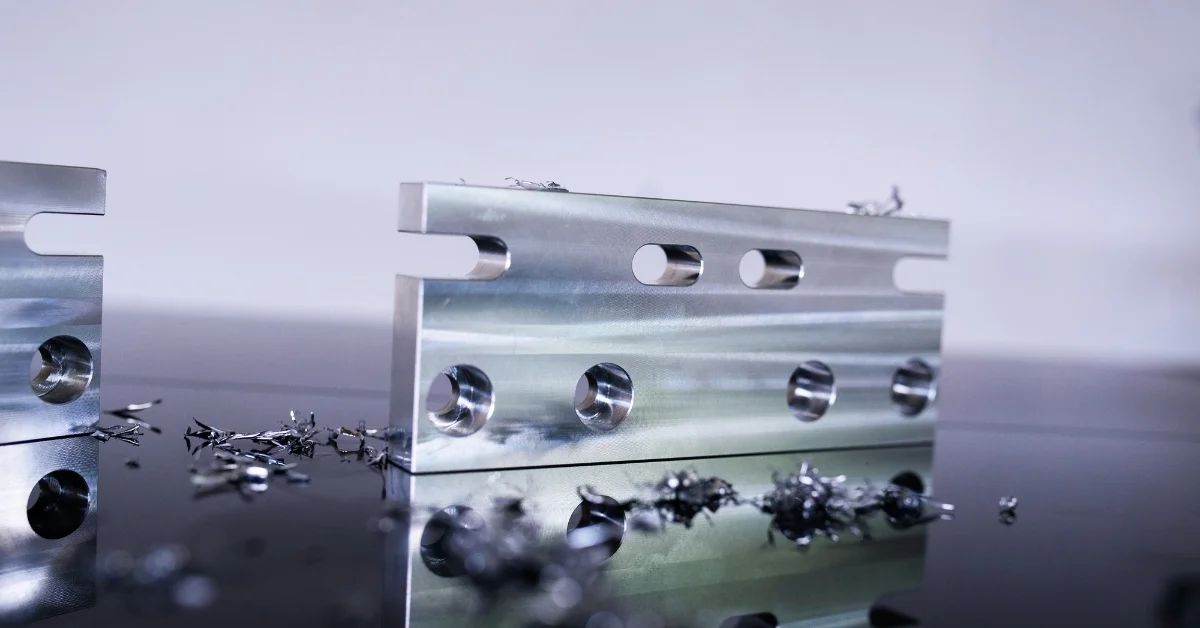

- Toughness and Accuracy- it is a superb precision standard machine and has finer tolerances than any other process of prototyping.

- Time-saving- it is extremely necessary for manufacturing prototypes as it saves time. It can support the mass production of components with excellency.

- Reduces Human Participation- many companies consider this as minimizing flaws due to machinists.

- Support Countless Materials- this is the reason why CNC rapid prototyping is one of the best processes as it can accommodate numerous materials.

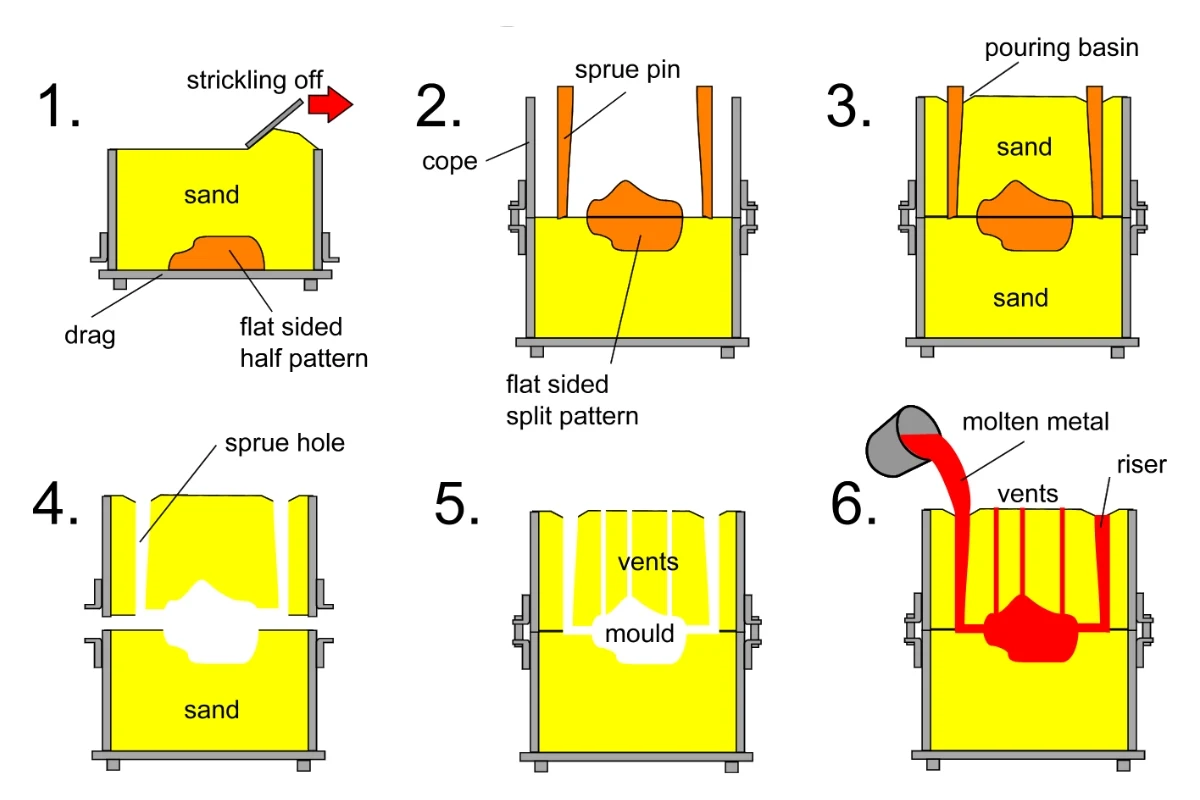

What are the Steps in CNC rapid prototyping?

- Design planning- the initial step in CNC rapid prototyping. This may incorporate dimensioning and placing the detail, planning for the fabrication and assembly, etc.

- Creation of 3D files- the chosen styles are turned into a 3D file, which characterizes the configurations, quality, and decorative specifications of the result component.

- Distinguishing of Manufacturing Sequence- when the 3D file is already created, the process of producing each detail is recognized. In addition to this, the arrangement of assembling steps is established to fabricate a prototype by applying a flawless CNC machining sequence.

- Programming- The cycle of the CNC manufacturing cycle is sent to the machine through the CNC program.

- Production- the CNC program will be put on the numerical control board of the CNC machine. The machine is ready for production mode and the CNC machining procedure happens.

- Trial- this is the last yet the most crucial pace in CNC rapid prototyping. This is where testing the capability and examining failure happens.

How much does CNC rapid prototyping machining cost?

When consulting for rapid prototyping services, the cost may depend on numerous factors. The details may involve the actual part proportions, machining practices, quantity, finishes, number of components, the volume of material used to fabricate a component, labor charge, and even the post-production handling.

What Does CNC Prototyping Mean?

In the simplest of terms, CNC prototyping is a type of machining process that is used before producing or manufacturing a single piece or a small batch of a product.

The necessity of CNC prototyping lies within the effectiveness and efficiency of a product. Let’s say that your product has successfully been market researched and it has been virtually tested, it still needs to undergo prototyping to further inspect and assess its overall efficiency and effectiveness.

CNC prototyping – or even prototyping in itself – reduces the impact of loss before releasing products.

Is CNC Prototyping the Same as Samples?

Yes and no – let me explain.

Prototypes, in layman’s term, are the FIRST SAMPLES before even starting the production process regardless of the volume. This means, even before the product has undergone feasibility testing, effectiveness testing, and even market research, it will be produced and prototyped.

The primary purpose of prototypes is to ensure that the merchandise or the products fit the description that is needed by the market of the client, and to see how it will play out.

Samples, on the other hand, are typically done right before or during production. Compared to prototypes, the main purpose of samples is to check the product in development – not even before starting its manufacturing or developing procedures.

Don’t confuse yourself in understanding prototypes from samples. Always remember that prototypes typically appear even before everything has been set for the manufacturing of the product, whereas samples are made to check its development and its exposure in the market.

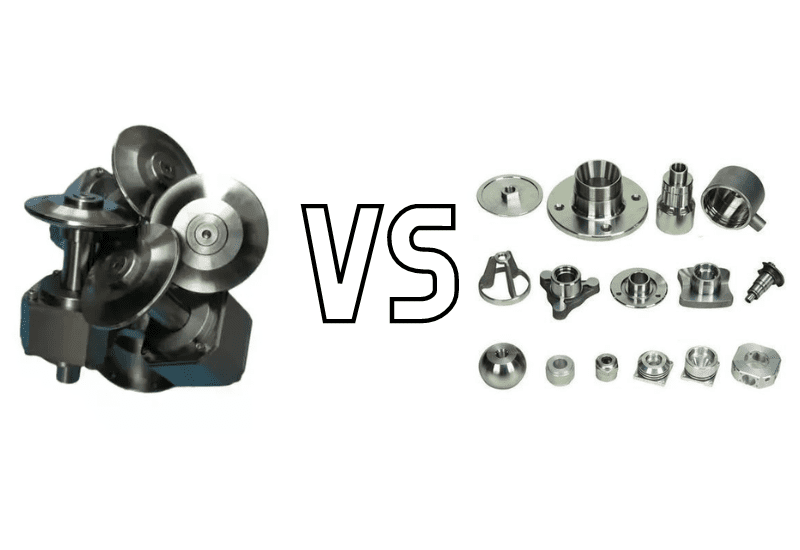

CNC Prototyping vs. CNC Rapid Prototyping

Many think that the single word – “prototyping” makes a huge difference in the area of manufacturing. So, in this question, we will be dwelling upon how both of them are different!

The simplest and most obvious answer to this question would be the speed – in traditional CNC prototyping, the prototypes are produced at a normal and regular rate, whereas in CNC rapid prototyping, the merchandise are usually produced at a much faster and more urgent rate.

How does this happen? Simple – Because of “HOW THEY ARE MADE.”

Traditional CNC prototyping makes use of simple CNC machines like CNC routers, mills, turning machines, and others. CNC rapid prototyping, on the other hand, makes use of highly advanced CNC machines, typically those that have more than one (1) axis.

What Are the Applications of CNC Prototyping?

The idea behind CNC prototyping is so relevant that without it, many of the businesses and industries today would not prosper and continue to develop. To name and cite a few of the MANY different applications of CNC prototyping, they include:

The idea behind CNC prototyping is so relevant that without it, many of the businesses and industries today would not prosper and continue to develop. To name and cite a few of the MANY different applications of CNC prototyping, they include:

- The Medical, Medicinal, and Pharmaceutical Industries

- Automotive, Motorcycle, and Aerospace Industries

- Military and Defense Sectors

- Marine and Maritime Industries

- Oil and Gas Industries

- Technology and Telecommunications Industry

- Chemical Industry

- And Many More!

Advantages of CNC Machining Prototyping

- The prototypes are highly precise and accurate

- All processes have urgency

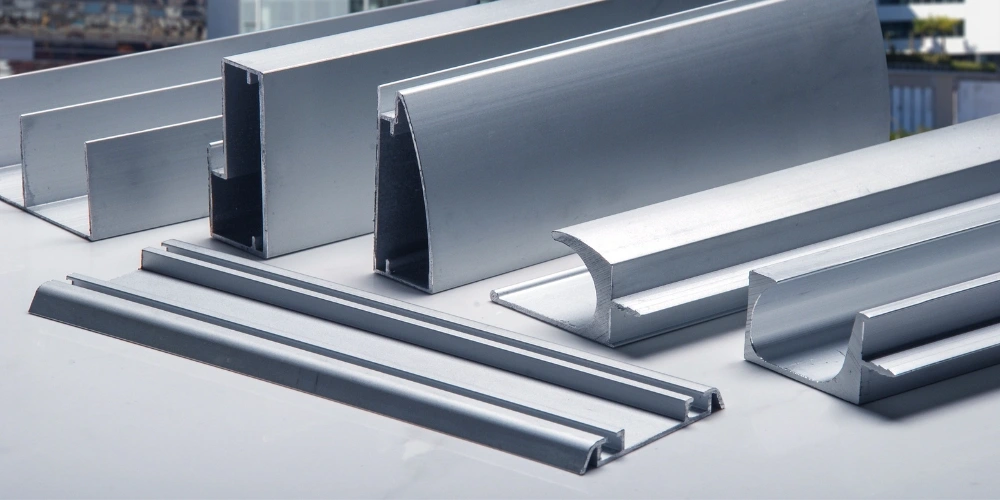

- They’ll surely be compatible with a lot of different materials and components

- Quality will never be an issue

Disadvantages of CNC Machining Prototyping

- Since they’re prototypes and they’ll be controlled by computers, there will be restrictions in the shape, form, or geometry of the prototype

- There’ll be more waste material because the product would not be manually adjusted by an operator

- It will cost more than the usual and regular prototyping processes

Are Chinese Prototyping Services Reliable?

Yes, as a matter of fact, Chinese prototyping services are considered the best and the most reliable in the market today. Besides the fact that they have the cheapest and most affordable offers, they also have all the resources needed that manufacturers from other countries would still have to order overseas – even from China.

Nothing is perfect – you will still be able to find a couple of drawbacks to patronizing Chinese CNC prototyping services, but one thing we can assure you is that it will be within your budget.

Where Can You Get the Best and Highest Quality of CNC Prototyping Service?

Being in business for more than a decade, we here at HDC Manufacturing have been trusted by numerous companies, businesses, and organizations not only in China, but also other foreign countries. We’re so trusted that we were able to help and assist all our clients with the prototyping services they needed!

Our capabilities in CNC prototyping include working on aluminum, steel, copper, and even low-carbon to mild-carbon steel. But wait, there’s more! HDC Manufacturing’s capabilities aren’t just limited to that – we’re also seasoned and experienced in working on other materials like polycarbonate or PC, high-density polyethylene or HDPE, nylon, Delrin, and many more!

If you are trying to look for an all-around CNC prototyping service provide that has all the necessary tools, materials, and equipment, HDC Manufacturing will always be a click away.

Apart from our continuous development in the business of CNC prototyping, we are also China’s go-to for other services such as aluminum forging, laser cutting services, 5-axis CNC machining services, and many others more!

Don’t hesitate to dial us, leave us a message, or shoot us a chat if you need help with budgeting! Contact us and we’ll send a free quotation over to you!

Resources: