Finding the Best CNC Harley Parts

Discover essential tips for sourcing high-quality CNC Harley parts for your motorcycle. Learn about the benefits of CNC parts, various materials and finishes, the manufacturing process, and top manufacturers. This guide also provides insights on customizing parts to meet your specific needs.

Harley CNC Motorcycle Parts Meaning

These simply are parts and components of Harley Davidson motorcycles that have been produced via a wide array of CNC machines and processes. Overall, the importance of CNC machines in the creation and manufacturing of bike and motorcycle parts has been considered the “new age” of experts in the manufacturing niche.

Companies are able to produce a variety of products more accurately, less timely, and with higher and better quality.

Understanding CNC Harley Parts

These are Harley Davidson parts produced using CNC machineries. You’ll typically find these in an Asian country (particularly China), as they are the region that’s most famous for the persistence and innovation of CNC manufacturing.

FUN FACT: OEM means original equipment manufacturing. This means that the materials used by the original manufacturer are the materials used by the other supplier. CNC Harley parts in China, though, are aftermarket items.

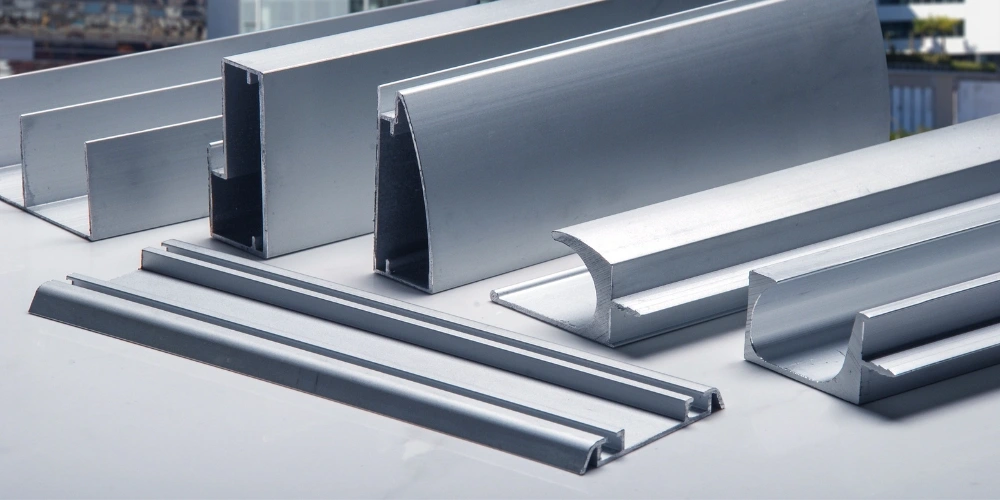

Materials Used in CNC Motorcycle Parts

The CNC motorcycle parts are manufactured from different materials customized to meet requirements. Lightweight, corrosion resistant aluminum is light heavy steel offers man’s demands and titanium which has an established strength-to weight ratio for high performance parts Flexibility with plastic and polymers, strength but low weight in carbon fiber, aesthetics and uses along brass offering resistance to corrosion. The wires are made from copper as it has a high conductivity and is corrosion resistant. This knowledge directs the process of choosing specific details to make short and accurate CNC motorcycle components.

Finishes Available For CNC Motorcycle Parts

CNC motorcycle components are made with the finishing as follows. Typical solutions are anodizing for color and corrosion resistance, powder coating for durability and variety, chrome plating to achieve a typical mirror finish, polishing for the premium look by which many manufacturers of car parts treat metal surfaces without adding extra materials or cost-intensive custom painting projects allow personalization while bead blasting provides a matte effect upon completion ceramic The above finishes satisfy various preferences for functionality and ultimately, the appearance and performance of these motorcycle components.

Design Limitations of CNC Motorcycle Parts

- Tool access for intricate designs

- Material limitations through hardness and heat conductivity

- The effect of machining time on costs

- Limitations in attaining some finishes of surfaces

- Restriction on part dimensions and masses

- Considerations for tolerances and accuracy

- Potential errors in complex designs

- Obstacles in prototyping some materials

Precision-Crafted Custom Harley Parts by HDC Manufacturing

- Aluminum Heel Toe Gear

- CNC Handle (Numerical Control)

- Nut Cover Bolts

- Alloy Handlebar

- Accessories

- And Many More!

The Meaning of CNC Milling Motorcycle Parts

Let’s break it down carefully and thoroughly first. To start, we will dissect what CNC milling means.

CNC milling is a subtractive manufacturing procedure that’s designed to remove or take off material from a workpiece in order to achieve the form, shape, size, and style required by the client.

In almost all projects, they’re either CNC milled or CNC turned to achieve the absolute 100% exact copy that the clients are looking for. And yes, CNC machines are capable of producing highly accurate products that are directed to the wants and needs of clients.

NOTE: CNC milling Harley parts is actually a relevant process for manufacturers to attain the exact shape and form you need!

Motorcycle Parts Made By CNC Machines

- Foot Pegs

- Swing Arm (Aluminum or Stainless Steel)

- Crash Slider

- Rear Shacks

- Twist Throttles

- Bar Ends

- Brake Rods

- Spring Forks

- And Many More!

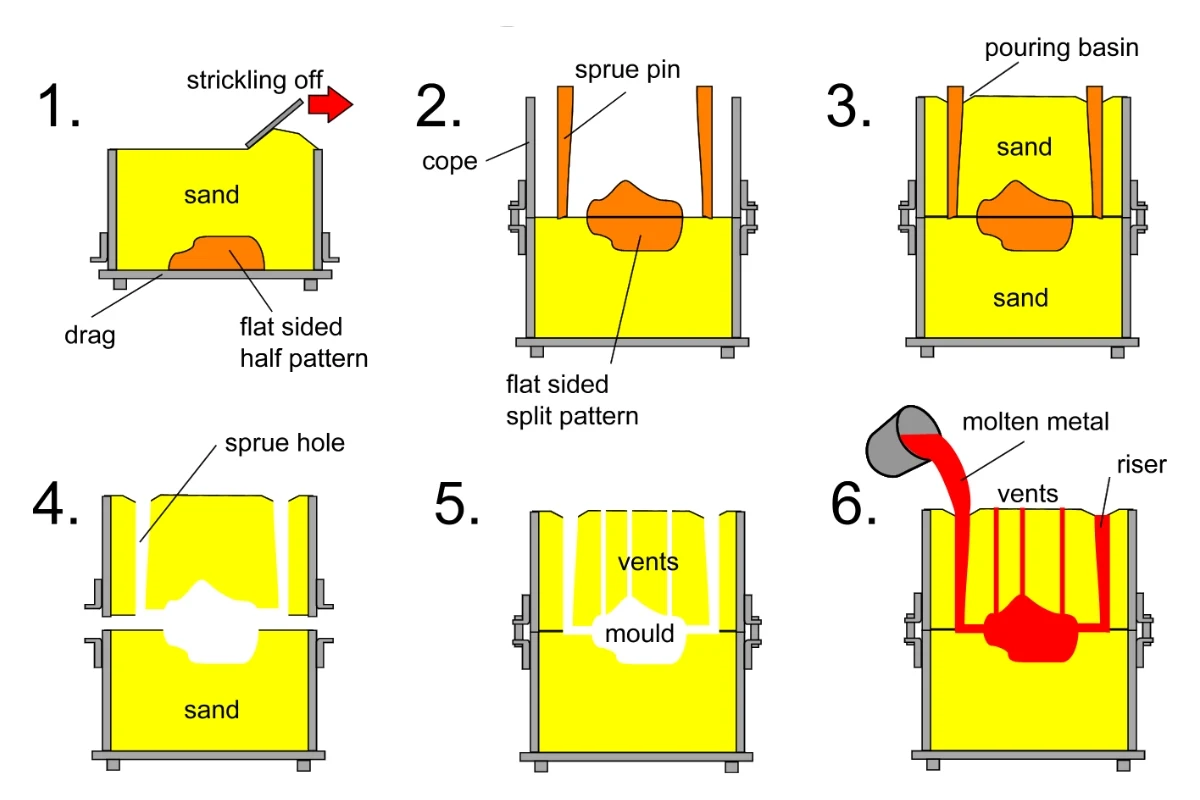

Process of Manufacturing CNC Harley Parts

Akin to other types of products made via CNC machines and processes, the typical process of how CNC Harley parts are made in sequence. Different manufacturers follow different blueprints or strategies for producing Harley parts, but for the benefit of everyone, this method is what’s considered to be the best and most generic.

Step #1: Material Selection and Gathering

First and foremost, the manufacturer needs to finalize the material that will be used for the production of the Harley Davidson component. While the company originally utilizes a combination of aluminum, titanium, brass, and carbon steel, several manufacturers play with it to deliver better quality.

Step #2: Plan Finalization

Once done, the overall plan and blueprint will be discussed and finalized. Everything will need to be checked from point A to point Z in order to avoid errors and mistakes in the machining procedures.

All measurements and coordinates will be set 100% exactly like how clients want it.

Step #3: CNC Machine Mounting/Loading

When it’s all ready, the material selected will be mounted and loaded onto the CNC machine. Usually, the machines used in this context would be CNC lathes, CNC grinders, CNC laser cutters, and CNC routers.

Step #4: CNC Machine Programming and Routing

Then, the machine selected will be programmed, routed, and set according to what the client wants and recommends. In this step, all machines involved will simultaneously be prepared in order for the manufacturing process to be smooth and seamless.

Step #5: Tool Geometry Setting and Execution

The next step would be the setting of the tool’s geometry. What’s meant by the tool’s geometry would be the overall condition of the tool like the temperature, the speed, the deepness of the cuts, locomotive movements, etc.

When the material is loaded and the machine has been programmed, it will be run and executed. The time it will take will depend on the complexity of the workpiece, as well as the volume.

Step #6: Finishing and Polishing

When the cutting is done, it will now undergo finishing and polishing. This step will be the step that will require human effort and intervention. Experts and inspectors will carefully check the finished products and will perform the smoothing or polishing of it.

Step #7: Full Inspection

The full inspection is the last step done to all CNC Harley and motorcycle parts in order to ensure that it is within – or beyond the quality that the clients are looking for.

NOTE: This is only a general structure of the CNC manufacturing procedure of Harley parts. Of course, some companies might be doing it differently.

Pros of CNC Harley Motorcycle Parts

- Suitable for the most complex and intricate of motorcycle components

- Cost-effective and affordable because you can purchase already-machined parts

- It can be made with 0 errors

- Effective if you are trying to develop prototypes

- Production and overall lead time is fast and urgent

Cons of CNC Harley Motorcycle Parts

- More material waste is produced in the process

- A bit costlier than traditionally-produced components

- Requires an expert operator to properly man the equipment, which conspires to the higher price

- Not flexible processing because everything will need to be set from the beginning

Wholesale CNC Motorcycle Parts

Purchasing CNC motorcycle parts wholesale will save you a lot of money, time, and effort! It has been proven that the fast turnaround time leads to a lot of improvement and development in the production process. Not to mention that you’ll be able to flip your products and introduce them to the market faster and more urgently compared to traditional and manual production!

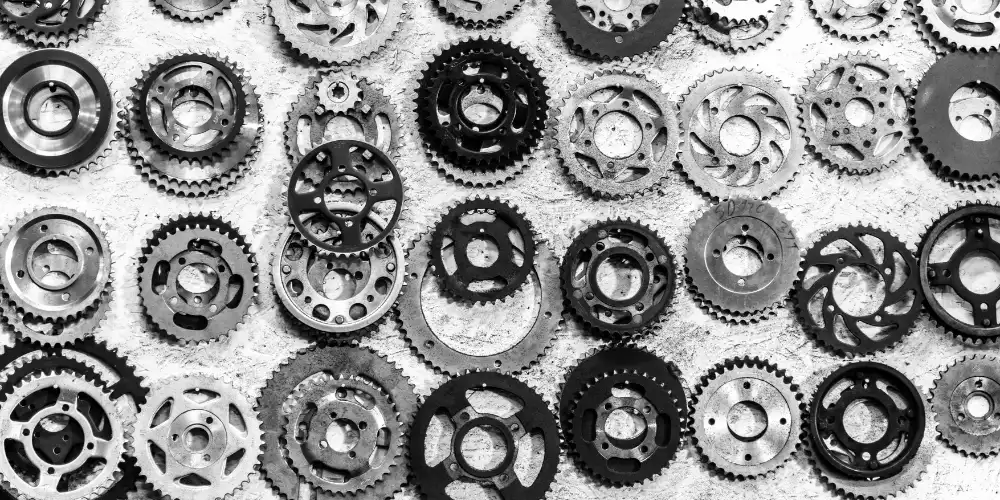

Harley Parts and Accessories Manufacturer That You Can Trust

Other than being Harley Davidson enthusiasts, we here at HDC Manufacturing have decades of experience in the manufacturing of aftermarket Harley parts. Equipped with multiple cutting-edge CNC machines and equipment, we can guarantee quality on all the Harley parts and components you need.

Nothing is obsolete with HDC Manufacturing – so long as we have what you need in our inventory, we’ll be able to help you with it!

Whether you need foot pegs, triple clamps, spacers, brake pedals, and other Harley-specific components, you can rely on us! Become one of the thousands of companies and businesses that trust and count on us!

Our expertise can bring you high-quality products in faster lead times! Get brake pedals, sprockets, bar end mirrors, and many more! HDC’s expertise aren’t just limited to that, though, as you can also count on us if you need help with aluminum forging, laser cutting, sheet metal fabrication, and many more!

Talk to us and we’ll send a free quotation over!

Custom CNC Motorcycle Parts From Manufacturers

To custom CNC motorcycle parts from manufacturers, follow these steps:

- Be specific on dimensions, materials and finishes you expect.

- Select a renowned CNC producer for high-quality motorcycle components.

- Communicate well with the manufacturer and make a good CAD drawing.

- Work with product selection material and get a quote on lead time.

- Alternatively build a design and performance prototype.

- State the quality control practices that ensure specified standards are adhered to.

- Deliver finishing alternatives such as anodisation or powder coating.

- To do so, the parties should define their payment terms in a more precise way and sign an agreement on all aspects.

- Maintain communication for coproduction.

- Verify specification compliance with inspected delivered custom parts.

This procedure guarantees a seamless and satisfactory customization of CNC motorcycle parts to suit your unique requirements.

Conclusion

In summary, it is vital to learn about the components of a CNC Harley motorcycle for die-hard enthusiast who wants quality and precise parts. These components produced in CNC machining processes present a number of benefits among which precision, fast production and compatibility with intricate designs stand out. In this regard, HDC is a reputable provider of OEM Harley parts online offering the most sought-after products that include aluminum heel toe gears, CNC handles and nut cover bolts to specific alloy handlebars among others.

Resources: