Small Batch CNC Machining: Integrating Flexibility with Precision

Explore the advantages and applications of small batch CNC machining, including production flexibility, product variability, and cost-effectiveness. This article delves into how CNC machining efficiently supports small batch production, adapting to rapidly changing market demands.

Understanding Small Batch Production

Small batch production is a type of production that refers to the high-quantity manufacturing of goods and products, but the units intended would be less than 500. It can still be categorized as a form of mass production, but with a substantial less quantity compared to regular mass production of 2,000+ units.

Various companies take advantage of this production style simply because of the volume promised, as well as the leverage of time to market.

The Benefits of CNC for Batch Production

Yes, CNC machinery and equipment are perfect for batch production – and it’s simply because of one (1) word – repeatability. Repeatability or the idea of being able to mirror the product quality multiple times is key to good batch production.

The usage of CNC machines can be efficient in small batch production as the workflow will be programmed and streamlined carefully and thoroughly.

DID YOU KNOW: Many companies treat CNC machines as the future not just of batch production, but also mass production.

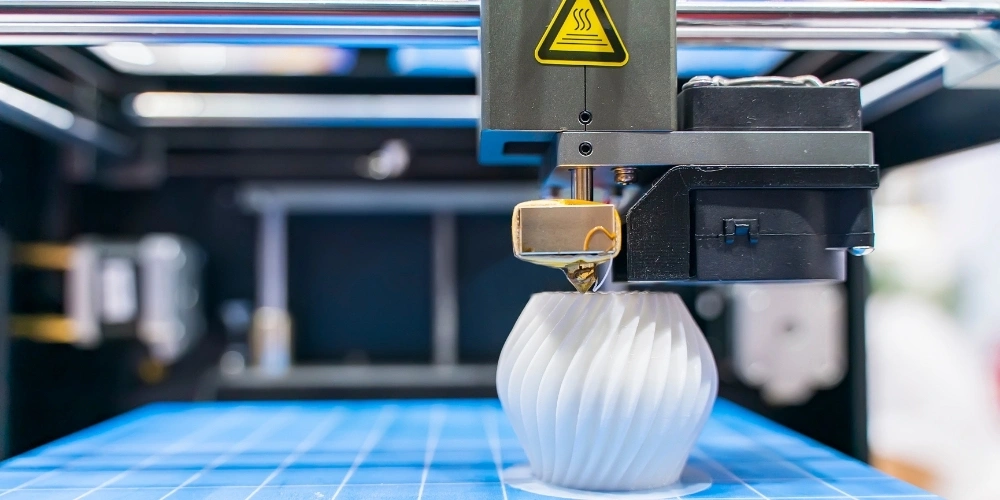

Understanding Small Batch CNC Machining

The term is pretty self-explanatory. It is the manufacturing process using highly advanced computer numerically-controlled (CNC) machines that are made for the purpose of manufacturing and/or producing in small batches (usually less than 500).

There is also what we call traditional batch making, which involved the use of traditional manual and semi-automatic machinery and equipment to produce the required quantity by a client.

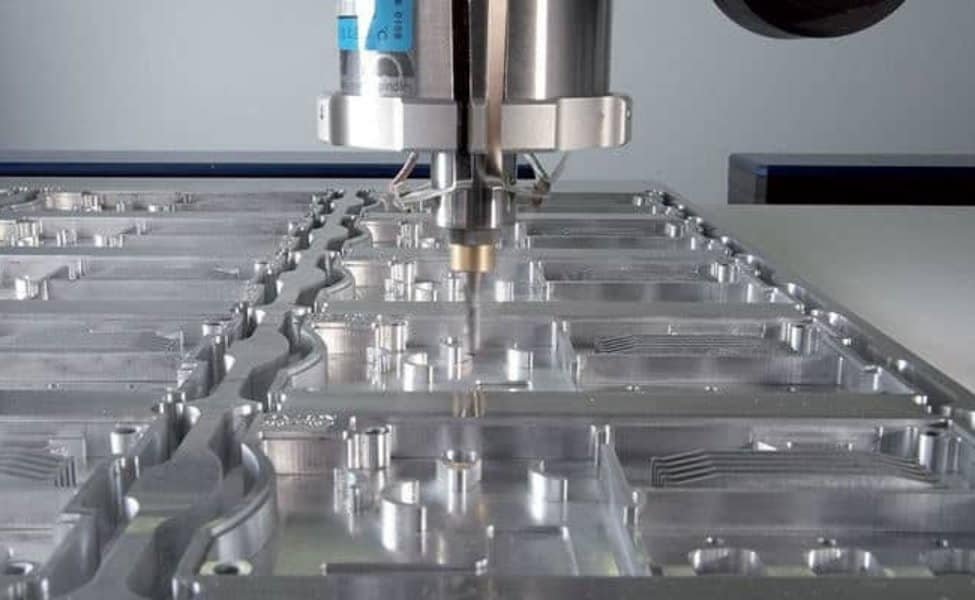

Examples of CNC Machining Tools

There are multiple types of CNC machines that are used for small batch manufacturing and production. Here at HDC Manufacturing, we take advantage of our conspired knowledge, skill, and experience in the field of industrial manufacturing.

The most common CNC machining tools you want to be aware of are:

CNC Lathes

CNC or computer numerically-controlled lathes are subtractive machines or equipment where the material or workpiece is mounted and is rotated by the spindle. A cutting tool will work on the material to reach the needed or ideal size, shape, and form.

Instead of workers adjusting the cutting tool, it will be automatically controlled by the program of the machine that has been set.

CNC Laser Machines

These are machines used for subtractive manufacturing by means of high-powered lasers. Their purpose is to cut, remove, or reduce the material of a given material or workpiece.

There’s no need for people to manually control these laser heads, it will be automatically-moving.

CNC Plasma Cutters

These are machines and/or equipment that’s used to cut through materials that are electrically conductive without the risks of employee or worker injury. It can seamlessly cut through copper, mild steel, titanium, bronze, lead, etc.

CNC Routers

Also a cutting material, CNC routers are automatic machines that are used for drilling, cutting, or milling. Instead of a regular router, there’ll be no person or worker needed to control the direction of where the router will go.

CNC Grinders

CNC grinders, lastly, are machines that utilize a rotating wheel in order to achieve successful material removal on difficult workpieces. Regular grinders would need about 2 people to manage it, but CNC equipment will only just need a single operator – and they’ll only require human intervention in the setup process!

Advantages of Small Batch Production

Small batch production relays a couple of pros and advantages, these include but are not limited to:

Production Flexibility

Flexibility in production is everything when it comes to manufacturing. Small batch production enables businesses to be able to produce goods using the same machine – and even customizations are present, it can be done!

Product Variations

By subjecting to small batch processing, there can be a ton of variation on the different aspects of products. What this simply means is, there can be differences in colors, sizes, as well as the design and shape of the product.

Better Quality Control

Another benefit would be the fact that small batch production will make it easier and more convenient to check the quality. Unlike mass production, assessors and inspectors will be able to check product quality more effectively and more efficiently.

Lower Costs

The fact that units will be purchased in bulk already means that the costs are lower for the product or service. These lower costs can help out a lot in managing the finances and directing it to other more important factors and facilities of the business.

Efficient Market Testing

Similar to better quality control, the market tests will be a lot simpler, easier, and more convenient for the business. They wouldn’t need to spend countless hours in testing it in the market because they can receive multiple results simultaneously.

Sustainability

Lastly, small batch processing can nurture a sustainable growth for the business because of the minimization of risk and errors early on. It would be a lot of products to tamper with, but not so much like mass production.

Disadvantages of Batch Production

It’s not always rainbows and butterflies – small batch production has its cons and disadvantages, too! They include:

Costly Errors

Compared to lower-scale production, small batch processing is inviting to costly errors. It might just be less than 500 units to begin with, but it’s still over a hundred units – what if you’re processing $100-value components?

More Downtime/Idle Time

A major change in the style or design means that there will be an extremely long downtime or idle time. Why? – Because you’ll need to change the entire manufacturing line to be able to pursue those changes.

The Need For Constant Attention

The more batches you’re running, no matter how small, would need constant eyes or attention to them. Even CNC machines can’t guarantee that a product will be 101% the same – the repeatability of CNC machines are for precision and accuracy, not for exact imitations.

These are the pros and cons of utilizing small batch CNC processing! As you can see, the pros heavily outweigh the cons!

The Cost of a Small CNC Lathe

A small CNC lathe can cost you upwards of $5,000 up to $100,000 depending on the complexity and comprehensiveness of the equipment you’re looking for.

Big-load manufacturing companies usually rest around the $20,000 and $40,000 range, while full-blown manufacturers and factories go up to $100,00.

Products that Small Batch CNC Machining Can Produce

Small batch CNC machining is a process that’s designed to produce bulk or multiple products at a single line. What this simply means is, all products and materials used for regular manufacturing can be produced with small batch CNC machining.Here with us at HDC Manufacturing, though, our specialties in small batch CNC machining include:

Small batch CNC machining is a process that’s designed to produce bulk or multiple products at a single line. What this simply means is, all products and materials used for regular manufacturing can be produced with small batch CNC machining.Here with us at HDC Manufacturing, though, our specialties in small batch CNC machining include:- Aluminum Parts and Components

- Testing Equipment

- Nuts, Bolts, Threads, and Other Tools

- Prosthetics Parts

- Hardware Materials

- Custom Components

- And Many More!

Batch Production Compare to Flow Production

100% Flow production, or more commonly known as single-line or one-piece production will be a lot slower and less efficient than small batch production. The advantage that one-piece flow production over small batch CNC processing, though, would be that of the space as well as potential costs and risks involved in the production line.

100% Flow production, or more commonly known as single-line or one-piece production will be a lot slower and less efficient than small batch production. The advantage that one-piece flow production over small batch CNC processing, though, would be that of the space as well as potential costs and risks involved in the production line.

Regular Process of Small Batch CNC Machining

The usual process of small batch CNC machining involves a few people and more materials. To help you identify it, here is the typical way of how they’re done:

- The material is fed and mounted onto the CNC machine.

- After that, an operator will program the machine (geometrically and directionally).

- Everything else such as (temperature, speed, quantity, etc.) will be toggled and programmed.

- When done quality analysts and inspectors will take one last look at the product to examine if it is within the specifications of the client.

- Lastly, it will be labeled and packaged according to the order.

Small Batch CNC Machining Manufacturer That You Can Trust

For 13+ years, we here at HDC Manufacturing have been continuously producing high-quality products via our small batch CNC machining procedures. Employed with the industries most reliable, most experienced, and most trusted sets of engineers, we can say that we’ve produced some of the industry’s best-quality parts and components for various types of machinery and equipment.

We are flexible in product-selection – you can even request for custom small batch units and components you need for your business!

You can trust us for whatever material you need, whether it’s stainless steel, aluminum, polycarbonate, thermoplastics, brass, and even OEM small batch machining, too!

Apart from small batch machining, we here at HDC Manufacturing can help you with metal fabrication parts, metal stamping parts, aluminum forging, CNC rapid prototyping parts, etc.

Reach out to us and get a free quotation for the orders you’re planning to get!

Custom Small Batch CNC Machining Parts From Manufacturers

Custom machined parts manufactured by small batch CNC companies produce ondemand precision products. It includes conversations yield technology details, prototype formation and choosing appropriate material with advancement in CNC machines for turning highly precision. Meticulous quality control procedures avoid deviations and adhering to the standards of industry, while cost-efficient manufacturing minimizes losses that bring about wastages. In the case small batch, orders often can have very short time frames to accommodate tight deadlines. Customers can opt for customized components ranging from prototypes to special products and replacement parts with adherence to stringent quality assurance standards as well as joint communications between the company that purchases those components.

Conclusion

Small batch CNC machining is a great opportunity for both businesses and individuals. It offers flexibility thereby producing customized goods that vary greatly in design, size and level of personalization. Thus, the process guarantees enhanced quality control and cost-effective approaches that make it a viable option for effective market testing practices. Although it poses some challenges, such as expensive mistakes and the need for constant attention to operations; The advantages of increased production flexibility combined with sustainability clearly outweigh the disadvantages. In conjunction with reliable manufacturers such as HDC Manufacturing, small batch CNC machining provides precision and quality in every component manufactured that can be trusted for various industries.

Resources: