1045 Carbon Steel: Composition, Properties, and Application Fields

- Walter

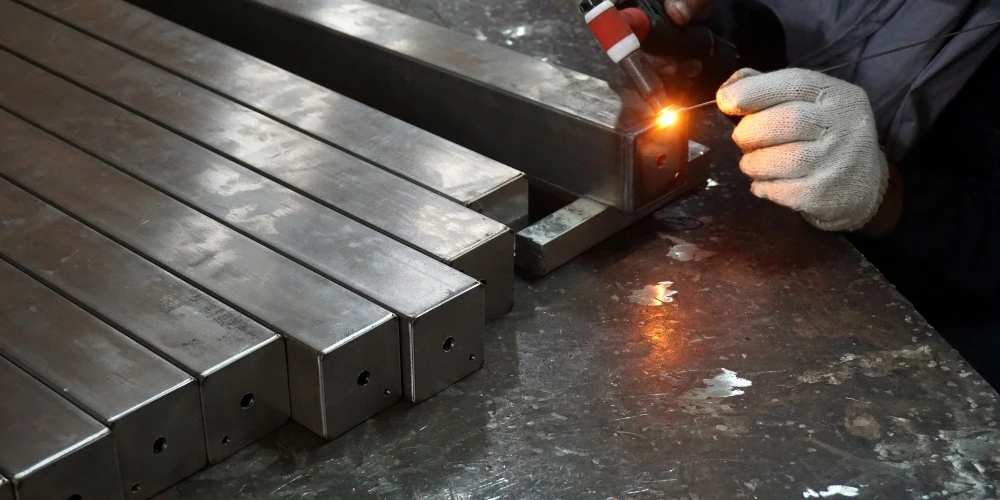

At HDC, our 13-year legacy in OEM metal craftsmanship propels us to excel in 1045 carbon steel processing. Commitment to quality and precision seamlessly extends to this robust material known for its strength and durability. A dedicated team ensures meticulous attention to detail and superior craftsmanship.

What sets HDC apart is our fully equipped, in-house manufacturing facility, fortified by skilled engineers and a design team. Proficiency spans diverse manufacturing techniques, from CNC processing precision to sheet metal finesse and casting artistry. HDC offers myriad customization options, tailoring each product precisely to project requirements.

HDC takes pride in advanced capabilities, showcased through our 4-axis and 5-axis CNC machining center. This cutting-edge technology enhances our ability to meet intricate demands of 1045 carbon steel projects. As pioneers, we seamlessly merge precision with innovation, providing a distinctive experience that surpasses industry standards. Choose HDC for your 1045 carbon steel machining needs and discover the perfect blend of expertise, commitment, and innovation.

What is 1045 Carbon Steel?

MnCr1045 carbon steel is one of the most spread medium-carbon alloys with a carbon content of 0.45%, appreciated for being a good balance of strength, hardness, machinability and affordability. This wide variety of applications includes gears, shafts, bolts, and other machine components This metal has good weldability and machinability that processing for the enhanced properties is possible, usable in the normalized state which provides uniformity in microstructure and mechanical properties.

How Is 1045 Carbon Steel Named?

1045 carbon steel is named based on its composition and standardization within the American Iron and Steel Institute (AISI) system. The “10” in 1045 denotes the basic carbon steel grade, while the “45” indicates its approximate carbon content of 0.45%. This alphanumeric designation provides a standardized way to identify and categorize carbon steels based on their composition and properties, facilitating communication and understanding within the industry.

Advantages and Disadvantages of 1045 Carbon Steel

1045 carbon steel being both an advantage and a disadvantage. Unlike other materials its versatility and affordability are of worth and can be applied in many different ways as it has balanced properties of strength, hardness, and ductility. This product of steel can be easily machined, so it is easy to make various parts of complex constructions with a smooth surface, and it is also applicable for heat treatment processes in order to adjust mechanical properties. On the other hand, it is also noted for the weldability which supporting fabrication and assembly, thus, enhancing its utility. On the other hand, the 1045 steel has some weaknesses such as moderate strength against alloy steels thus it cannot be used in applications under high pressures or abradable operations. Secondly, it may be vulnerable to corrosion, or its components might be brittle under heavy load. Therefore, precautions or protective measures may be necessary. The disadvantages, together with the drawbacks of limited abrasion resistance and difficulties in machining, have to be carefully assessed when making a choice of materials for certain purposes especially in severe conditions.

Chemical Composition of 1045 Carbon Steel

1045 Carbon steel is medium carbon steel and contains low alloy resulting that it being unsuitable for carburizing and cyaniding. It is widely used in the automotive, agriculture, and construction industry due to its high wear resistance, medium tensile strength, and high impact properties, such as crankshafts, hubs, axles, sockets, rolls, casters, and other machinery parts.

| Component | Wt.% |

| Carbon (C) | 0.42 – 0.50 |

| Iron (Fe) | 98.51 – 98.98 |

| Manganese (Mn) | 0.60 – 0.90 |

| Phosphorus (P) | 0.0 – 0.04 |

| Sulfur (S) | 0.0 – 0.05 |

The Influence of the Composition on the Properties of 1045 Carbon Steel

The 1045 carbon steel composition markedly impacts its characteristics. However, carbon content of 0.45 % renders 1045 steel as an alloy having the balanced character of strength, toughness and ductility which is suitable for diverse applications. In this case, the medium carbon content gives the plate good tensile strength and wear resistance while allowing machinability and weldability. Additionally, trace elements like manganese, phosphorus, and sulfur can also be part of the mix and can influence its characteristics. The presence of manganese gives the alloy better hardenability and strength; manganese is also able to increase the alloy’s corrosion resistance. Sulfur acts as lubricant and thus increased machinability, but can cause brittleness in addition to heavy tensile parts. In general, the controlled composition of 1045 carbon steel provides a wide range of applications for it as this mixture of mechanical properties fits almost every means of use, from machine and shafts to gears and shafts.

Mechanical Properties of 1045 Carbon Steel

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 585 MPa | 84800 psi |

| Tensile Yield Strength | 450 MPa | 65300 psi |

| Elongation at Break | 12 % | 12 % |

| Reduction of Area | 35 % | 35 % |

| Hardness, Brinell | 163 | 163 |

| Hardness, Knoop | 184 | 184 |

| Hardness, Rockwell B | 84 | 84 |

| Hardness, Vickers | 170 | 170 |

| Modulus of Elasticity | 206 GPa | 29900 ksi |

| Bulk Modulus | 163 GPa | 23600 ksi |

| Shear Modulus | 80.0 GPa | 11600 ksi |

| Poissons Ratio | 0.29 | 0.29 |

Physical Properties of 1045 Carbon Steel

| Physical Properties | Metric | English | Comments |

| Density | 7.87 g/cc | 0.284 lb/in² | |

| 1045 Steel Machinability | 65% | 65% | |

| Electrical Properties | |||

| Electrical Resistivity | 0.0000162 ohm-cm | 0.0000162 ohm-cm | Temperature 0.000 °C/32.0°F, annealed condition |

| 0.0000223 ohm-cm | 0.0000223 ohm-cm | Temperature 100 °C/212°F, annealed condition | |

| Thermal Properties | |||

| Specific Heat Capacity | 0.486 J/g-°C | 0.116 BTU/lb-°F | Temperature >=100°C/212°F, annealed |

| Thermal Conductivity | 51.9 W/m-K | 360 BTU-in/hr-ft²-°F | estimated based on similar materials |

Equivalent Materials of 1045 Carbon Steel

| EU | EN | C45 (1.0503) | ||

| USA | – | 1042 1045 Gr.1043 | ||

| Germany | DIN,WNr | C45 | ||

| Japan | JIS | S45C | ||

| France | AFNOR | AF65C45 C45 | ||

| England | BS | 070M46 50HS | ||

| Italy | UNI | 1C45 C45 | ||

| Spain | UNE | C45k | ||

| China | GB | 45 | ||

| Sweden | SS | 1650 | ||

| Poland | PN | 45 | ||

| Czechia | CSN | 12050 | ||

| Austria | ONORM | C45SW | ||

| Russia | GOST | 45 | ||

| Inter | ISO | C45 | ||

Common Processing Methods Used for 1045 Carbon Steel

1045 Carbon Steel processing techniques include machining, heat treating, welding, cold working, and other surface treatments. This machine is one with exceptional machinability, it is easy to turn, mill and drill and hence it makes precise dimensions and smooth finishes. For instance, through heat treatment methods such as quenching and tempering, its mechanical properties can be altered, or various welding techniques can be used for fabrication. Cold forming processes, which are represented by cold drawing and forging, enable shaping, but also the improvement of properties. Furthermore, carburizing and nitriding of the surface are what improves wear and corrosion resistance. These versatile processing methods allow this 1045 Steel to be utilized in the various needs of most of the industries.