Comprehensive Guide to CNC Clutch Slave Cylinders for Optimal Performance

Explore the vital role and benefits of CNC Clutch Slave Cylinders in manual transmission vehicles. Our guide delves into their functions, manufacturing advantages, and customization options to enhance your driving experience.

Understanding CNC Clutch Slave Cylinder

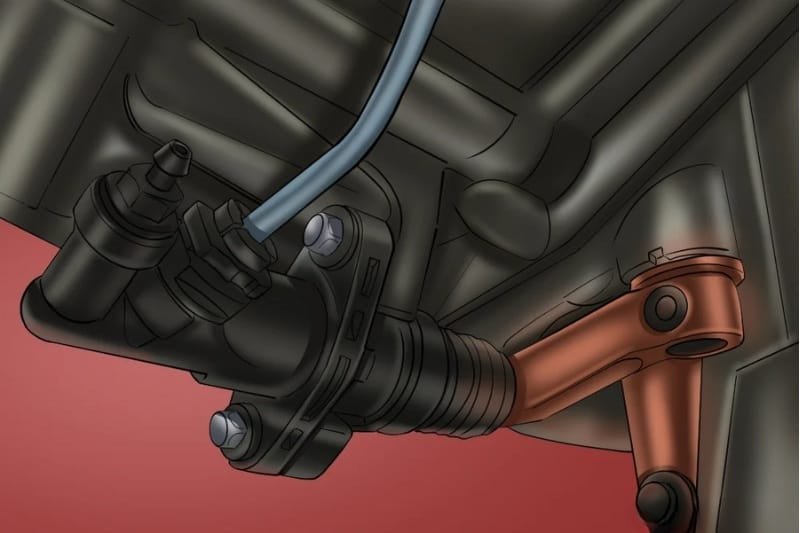

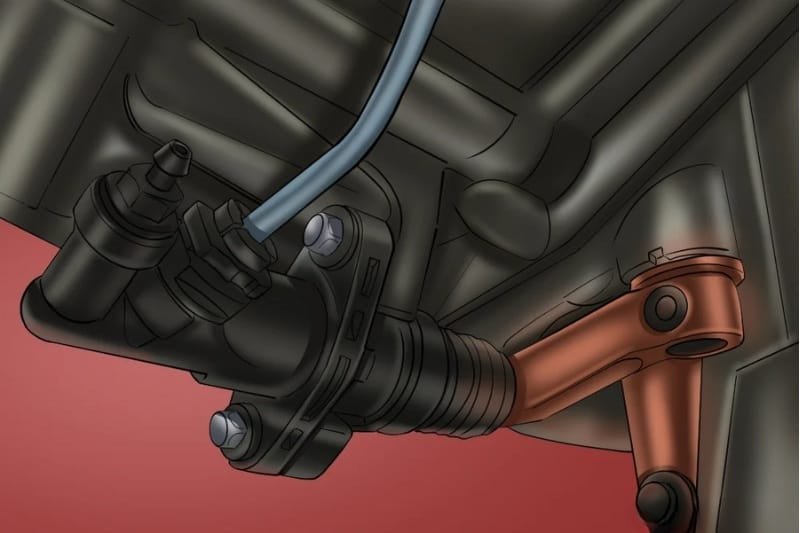

CNC Clutch Slave Cylinders are essential components of hydraulic clutch systems of manual transmission vehicles. Their function is to turn the hydraulic pressure from the master cylinder into mechanical force and enable clutch engagement and disengagement. The precision-made ones, manufactured by CNC machining processes are preferred due to their strength and clutch performance characteristics. It can ensure better clutch operation, a good pedal feel and improved wear resistance of the clutch itself. Therefore, they are often targeted as replacement parts in the aftermarket for those wanting to enhance their vehicle’s clutching power.

Application of Clutch Slave Cylinder

Clutch slave cylinder is a key element in the hydraulic clutch system of manual transmission vehicles. Its fundamental purpose is to allow smooth gear changes through the conversion of hydraulic pressure from the master cylinder into mechanical force. As soon as the driver steps on the clutch pedal, hydraulic fluid is delivered to the clutch slave cylinder pushing into it against the clutch release bearing disconnecting and effecting shifting gears. This cylinder is critical in ensuring such efficient and controlled clutch engagement which can be used on high hill starts and low-speed maneuvers. Additionally, it improves pedal feel, allowing the driver to more accurately determine when an engagement point is reached. It prevents abrasion of clutch components and hence increases the duration that they can be used. Certain enthusiasts choose extra off the shelf upgrades such as CNC Clutch Slave Cylinders to enhance performance and reliability under specific driving situations.

Working Principle of a Clutch Slave Cylinder

The operation of a clutch slave cylinder is relatively simple, yet it plays a crucial role in the functioning of a manual transmission.

Clutch Disengagement

When the clutch pedal in a manual vehicle is pressed, it triggers the clutch master cylinder, propelling hydraulic fluid through the lines to the clutch slave cylinder. This pushes the cylinder’s piston forward, Consequently, this process disengages the clutch from the engine, enabling smooth and effortless gear changes.

Clutch Engagement

Releasing the clutch pedal leads to the retraction of the clutch slave cylinder’s piston. This action allows the hydraulic fluid to flow back into the cylinder, resulting in the clutch re-engaging with the engine. As a result, power is transferred from the engine to the wheels.

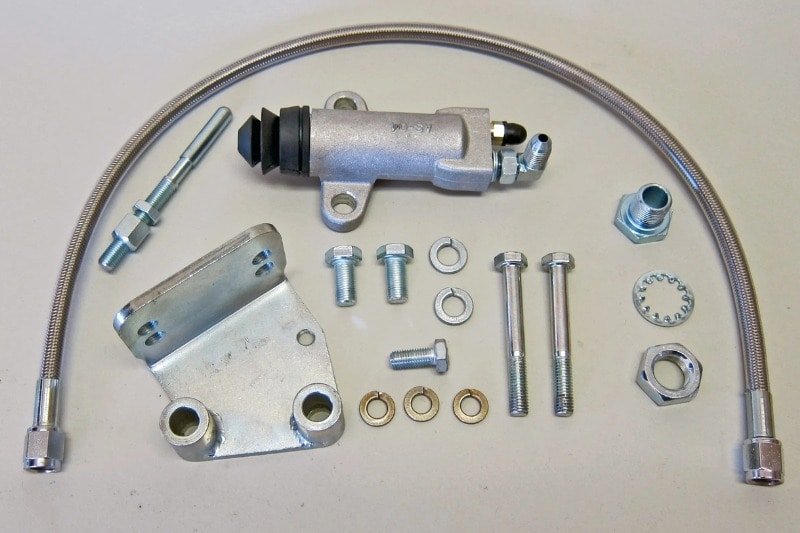

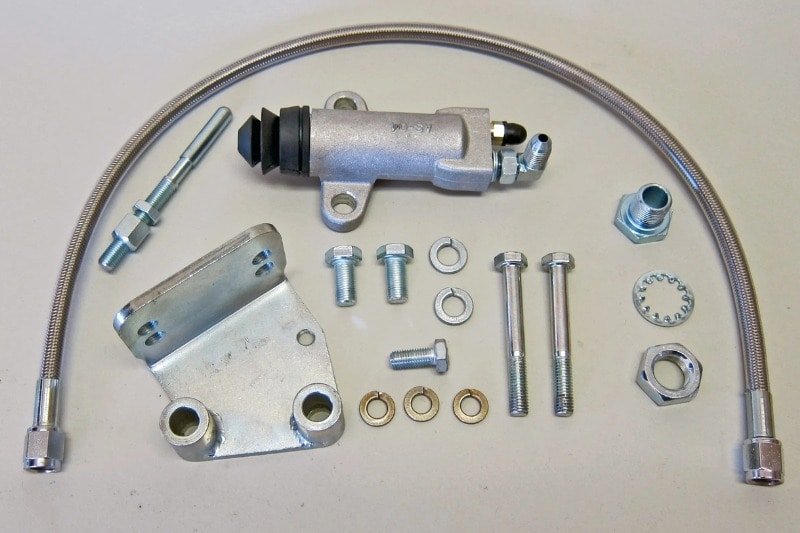

Components Make Up a Clutch Slave Cylinder

A clutch slave cylinder comprises a cylinder body housing key components: a piston, seals and O-rings for hydraulic sealing and hydraulic fluid ports for conducting the liquid entry and exit. It also encompasses a push rod, which is connected to the piston and transmits force to the clutch release bearing. Some models have a dust boot for protection and secure mounting flange for the attachment to transmission or clutch housing. These features work together to transform hydraulic pressure to mechanical energy, so the clutch can be engaged or disengaged, thus facilitating a manual transmission system.

The Enhancement of Clutch Performance by the Clutch Slave Cylinder

In a vehicle that uses manual transmission, the clutch slave cylinder can very well improve the performance of the clutch. It is a critical aspect in promoting the smoother and controlled clutch engagement and disengagement, resulting in several performance advantages. Through effortless gear changes and eliminating harsh starts or jerks, the clutch slave cylinder contributes to comfortable driving as well as smooth operation. It also improves the pedal feel, allowing a better sense to the drivers for clutch engagement point. In addition, this feature leads to minimized clutch assembly wear such as the clutch plate, pressure plate and release bearing making them more durable. Followers may opt for replacement with complex parts such as CNC Clutch Slave Cylinders to achieve better capacity and efficiency hence making the clutch system more sensitive.

Clutch Slave Cylinder Used for High-Performance Applications

Although generally not linked with high-performance applications, clutch slave cylinders can still play a role in enhancing the quality of the clutch’s performance even within such situations. Going for high end options such as ceramic CNC Clutch Slave Cylinder will make you feel the difference in terms of pedal feeling, smoother engagement and lesser wearing out of clutch components. These advantages are beneficial for high-performance vehicles because they allow the faster and more precise changes of gears, which in turn leads to improved overall performance. Still, one needs to take care of other clutch system components like the flywheel, clutch disc, and pressure plate to ensure that an adequate upgrade is applicable for high-performance applications adequately.

Benefits of Manufacturing a Clutch Slave Cylinder Using CNC

The production of a clutch slave cylinder via CNC machining allows for several notable benefits, including the highest degree of precision and accuracy in component design with complex geometry, quality consistency, and high manufacturing efficiency. Due to the inherent flexibility of CNC machining, material consistency and adaptability are enhanced to allow for stock replacements as well as high-performance applications. Furthermore, sophisticated monitoring and quality control processes make sure that the clutch slave cylinders are made according to high standards of specifications during the manufacturing stage.

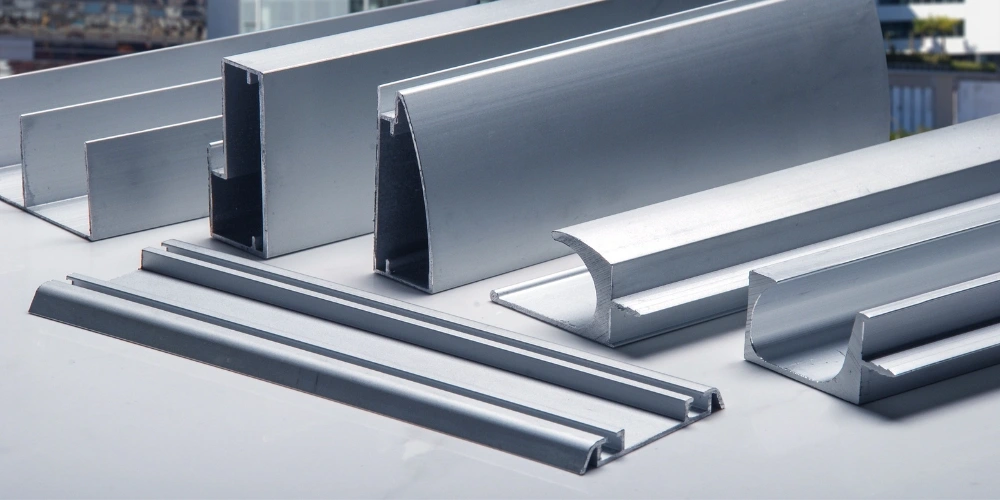

Materials Commonly Used in CNC-Manufactured Clutch Slave Cylinders

Aluminum, steel, stainless steel and plastics materials are used in CNC-machined clutch slave cylinders. For applications where strength and durability are important, steel might be more appropriate while lightweight, corrosion resistance would make aluminium a preferred option. There are some specialized cylinders that use high-quality plastics or composites because of their qualities as they include resistance to corrosion under harsh environments, weight reduction and chemical inertness. The material to be used in this case is dependent on the mode of transportation and the application of it, with aluminum and steel being preferred for their dependability strength.

Maintenance Clutch Slave Cylinders

Clutch Slave Cylinders are designed to be relatively low-maintenance. However, it’s important to periodically inspect them for any leaks, check the hydraulic fluid level, and examine the cylinder for signs of wear or damage. Regular maintenance ensures consistent clutch performance.

Customizability of CNC Clutch Slave Cylinders

CNC Clutch Slave Cylinders are often customizable for use in both motorcycles and vehicles with manual transmissions. Drivers can choose specific features, such as the cylinder’s finish, color, or even the inclusion of additional functionalities. Customization allows for personalization and optimization of clutch performance in either context.

Customize a CNC Clutch Slave Cylinder

The process of customizing a CNC clutch slave cylinder from manufacturers is systematic. Begin by assessing your unique needs considering the type of vehicle, performance aspects, materials used and any special design features. Secondly, identify manufacturers specialized in CNC machining and clutch components that are capable of delivering custom-made slave cylinders. Discuss with probable manufacturers in detail, giving technical specifications and design requirements. Work closely with their engineering team using CAD modeling and prototyping for design optimisation. Selection of material is important in terms of strength and corrosion resistance. Talk about the quality control procedures for stringent testing and inspection of the customized cylinder.

Also, find out what quantity is needed, set a schedule for production and specify price, payment terms and any costs. If such is the case, ask for prototypes for testing and verification before commencing full scale production. Focus on quality assurance for specifications. Finally, discuss post-sale service like warranties, returns and ongoing support with which you ensure a seamless customization process as well as delivering a product that fits your needs.

Conclusion

CNC Clutch Slave Cylinders are vital components for both motorcycles and vehicles with manual transmissions, and understanding their functions and benefits can enhance the driving experience. Whether for daily commuting or high-performance applications, a well-maintained and customized Clutch Slave Cylinder can make a significant difference in the performance of these vehicles.

Resources: