Custom-made valve covers have become a popular choice among automotive enthusiasts, offering a unique way to enhance the aesthetics of your vehicle while adding a personal touch. When delving into the world of custom valve covers, there are several key considerations to keep in mind to ensure you get a product that not only looks great but also meets your performance needs.

Table of Contents

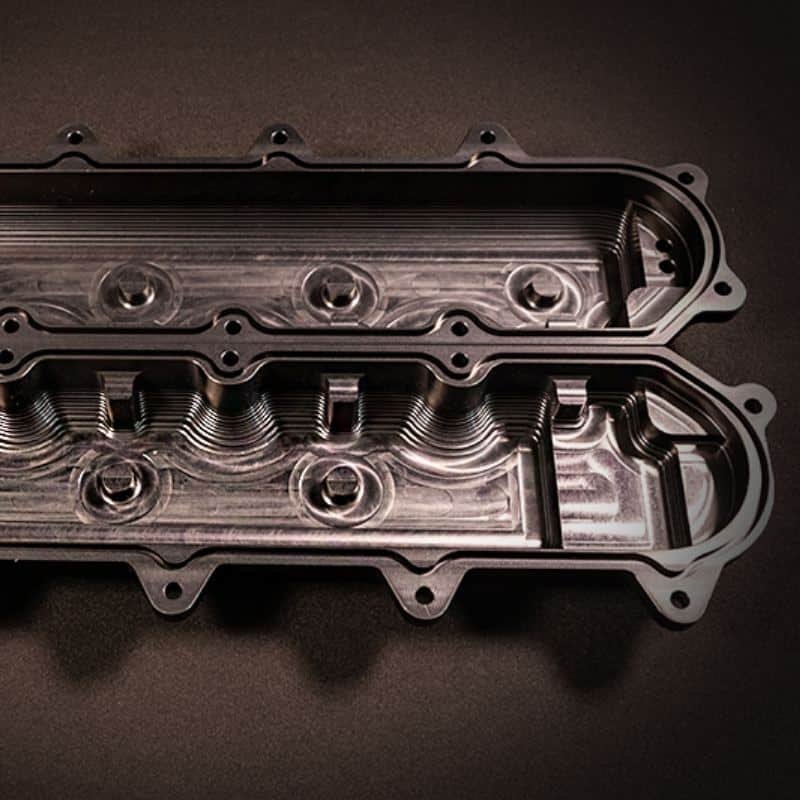

What are Valve Covers

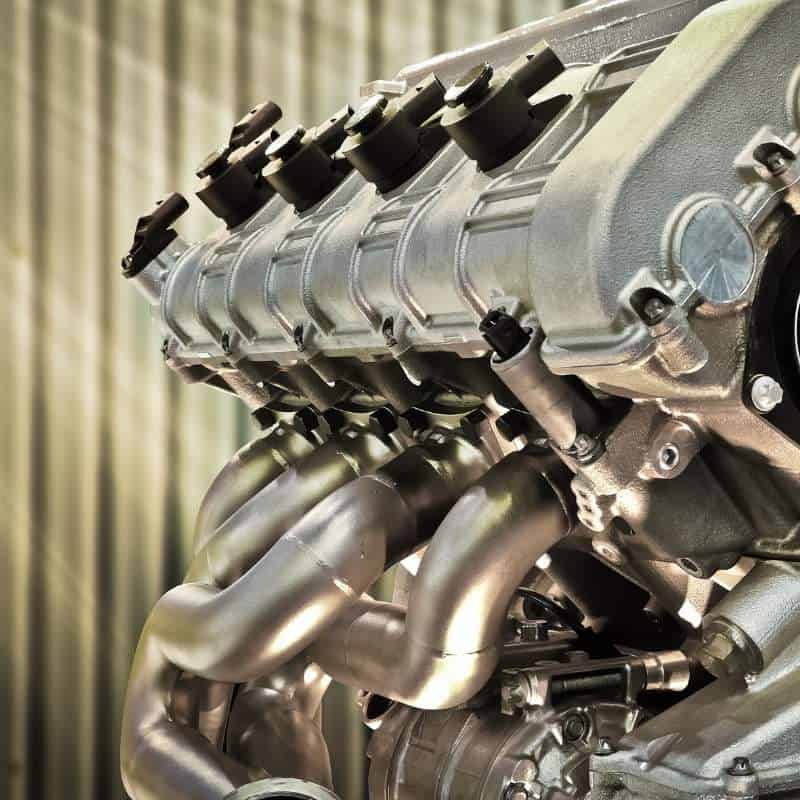

Valve covers are protective components in internal combustion engines, covering the cylinder heads to shield valvetrain elements like valves and camshafts from debris and contaminants. Composed of metal, they also contain and maintain the lubricating oil needed for proper engine function. Besides their protective role, valve covers are often customized for both performance and aesthetic purposes by car enthusiasts, who may replace stock covers with aftermarket options featuring additional functionalities such as oil fill caps and PCV valves. In essence, valve covers are essential for ensuring the cleanliness, functionality, and overall longevity of an engine’s critical components.

Function of Valve Covers

The primary functions of valve cover in an internal combustion engine include:

- Sealing: Ensures a tight seal for valve train components, preventing oil leaks and maintaining engine cleanliness.

- Protection: Acts as a protective shield for critical valve train elements, ensuring longevity and proper functionality.

- Maintenance Access: Features a removable design for easy access to valves, facilitating routine maintenance without extensive disassembly.

- Aesthetic Enhancement: Customized for visual appeal, contributing to the engine compartment’s overall aesthetics and allowing for personalization.

- Performance Considerations: Custom designs may optimize engine performance, focusing on ventilation, heat reduction, and enhanced airflow within the valve train.

- Heat Management: Incorporates designs for effective heat dissipation, contributing to maintaining optimal engine temperatures and preventing overheating.

Materials and Finishes for Valve Covers

When it comes to valve covers, the choice of materials and finishes is crucial for both functionality and aesthetics. Here’s a breakdown of common materials and finishes used in manufacturing valve covers:

Materials:

- Aluminum: Lightweight and durable, aluminum is a popular choice for valve covers. It offers good heat dissipation and is often used in performance applications.

- Steel: Known for its strength, steel provides robust protection for valve train components. However, it is heavier than aluminum and may require additional coatings for corrosion resistance.

- Alloy Composites: Various alloy composites may be used, combining different metals for enhanced strength, heat resistance, and weight benefits.

Finishes:

- Polished Finish

- Powder Coating

- Anodized Finish

- Painted Finish

- Natural/Brushed Finish

- Chrome Finish

Manufacturing Process for Custom-Made Valve Covers

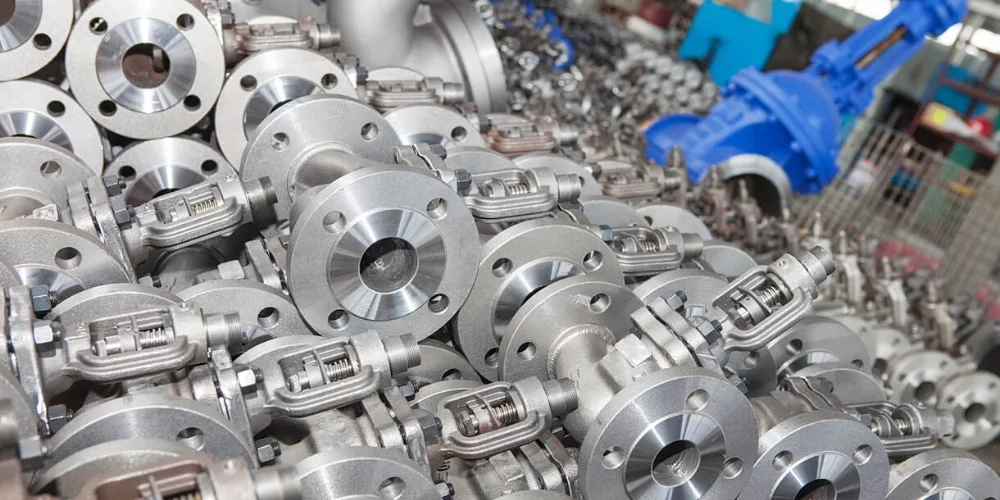

There are several manufacturing processes that can be used to produce valve covers. The choice of method depends on factors such as material, design complexity, and production volume. Here are some common manufacturing processes for valve covers:

- Casting: Pouring molten metal into a mold to form the valve cover’s shape. Ideal for complex designs and cost-effective for large production.

- Machining: Removing material from a solid block using CNC for precision and intricate designs. Suitable for lower-volume production.

- Stamping: Pressing sheet metal between dies to create valve covers with simple shapes. Cost-effective for high-volume production.

- 3D Printing/Additive Manufacturing: Building up layers to create valve covers, suitable for complex and customized designs. May be less cost-effective for large volumes.

- Die-Casting: Injecting molten metal into a mold under high pressure for fast and efficient production, especially for metals like aluminum or zinc. Ideal for high-volume manufacturing.

The choice of manufacturing process depends on factors such as material requirements, production volume, design complexity, and cost considerations. Manufacturers often evaluate these factors to determine the most appropriate method for producing valve covers based on their specific needs.

Compare Custom-Made Valve Covers to Original Factory One

Custom-made valve covers offer greater design flexibility and material choices, allowing for unique aesthetics and tailored performance. While they tend to be more expensive and have longer production times, the precision, quality control, and exclusivity they provide can be appealing to those seeking a personalized touch. In contrast, original factory valve covers are cost-effective due to mass production, with standardized designs, materials, and shorter production times. While lacking the customization options of custom-made covers, factory covers ensure compatibility with a wide range of vehicles and are widely available, making them a practical choice for those prioritizing efficiency and affordability. The choice between custom-made and factory valve covers ultimately depends on individual preferences, budget constraints, and the desired level of personalization.

Installation of Custom-Made Valve Cover

Installing a custom-made valve cover can add a personalized touch to your engine and enhance its aesthetic appeal. Here’s a general guide on how to install a custom valve cover:

- Prepare the Work Area: Ensure the engine is cool before starting. Place the vehicle in park or neutral, and engage the parking brake. Open the hood and locate the existing valve cover.

- Disconnect the Battery: To ensure safety, disconnect the negative terminal of the battery.

- Remove Existing Valve Cover: Loosen and remove any components obstructing access to the valve cover. Carefully detach the existing valve cover, taking note of any hoses, wires, or bolts that need to be removed.

- Clean the Surface: Thoroughly clean the cylinder head surface where the valve cover sits. Remove any residue, old gasket material, or debris.

- Inspect and Replace Gaskets: Check the condition of the valve cover gasket. If it’s worn or damaged, replace it with a new one.

- Install the Custom Valve Cover: Carefully position the custom valve cover in place. Hand-tighten the bolts to ensure proper alignment before fully tightening them.

- Torque the Bolts: Use a torque wrench to tighten the valve cover bolts to the manufacturer’s specifications. This is crucial to prevent leaks and ensure a proper seal.

- Reconnect Hoses and Wires: Reattach any hoses, wires, or components that were disconnected during the removal process.

- Refill Engine Oil: If necessary, check and refill the engine oil to the recommended level.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Start the Engine: Start the engine and check for any leaks around the valve cover. If leaks are detected, inspect and re-tighten the bolts as needed.

Maintenance Tips

To ensure the optimal performance and durability of your custom-made valve cover, adhere to a routine maintenance schedule. Periodically inspect the valve cover for leaks, tightening bolts as needed. Adhere to recommended oil change intervals, checking the valve cover and gasket for wear during each oil change. Promptly replace a deteriorating gasket to maintain a proper seal. Keep the engine bay clean to prevent debris accumulation on the valve cover, and vigilantly monitor engine performance for any abnormalities that may indicate issues with the valve cover or gasket. Always consult the specific guidelines provided by the custom valve cover manufacturer for additional instructions.

Custom Valve Covers from Manufactures

To acquire custom valve covers from manufacturers, start by researching reputable companies such as HDC that offer customization services. Contact the chosen manufacturer directly to discuss your specifications, including material, finish, and design preferences. Review design proofs and quotes provided by the manufacturer, ensuring they align with your expectations and budget. Inquire about production lead times, quality assurance processes, and payment terms. Once satisfied, place your order, and upon receiving the custom valve covers, follow the manufacturer’s guidelines for installation or seek professional assistance if needed.

Conclusion

Custom-made valve covers offer a fantastic opportunity to add a personal touch to your vehicle. Beyond aesthetics, they provide a sense of identity and individuality on the road. By carefully considering materials, designs, and manufacturers, you can embark on a customization journey that enhances both the look and performance of your vehicle. Explore the possibilities, communicate openly with manufacturers, and enjoy the process of making your vehicle uniquely yours.