Overview

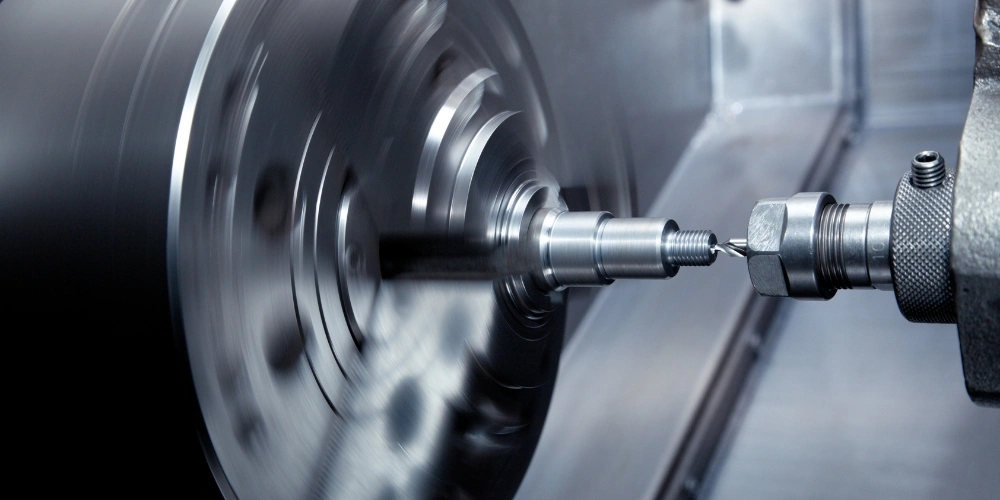

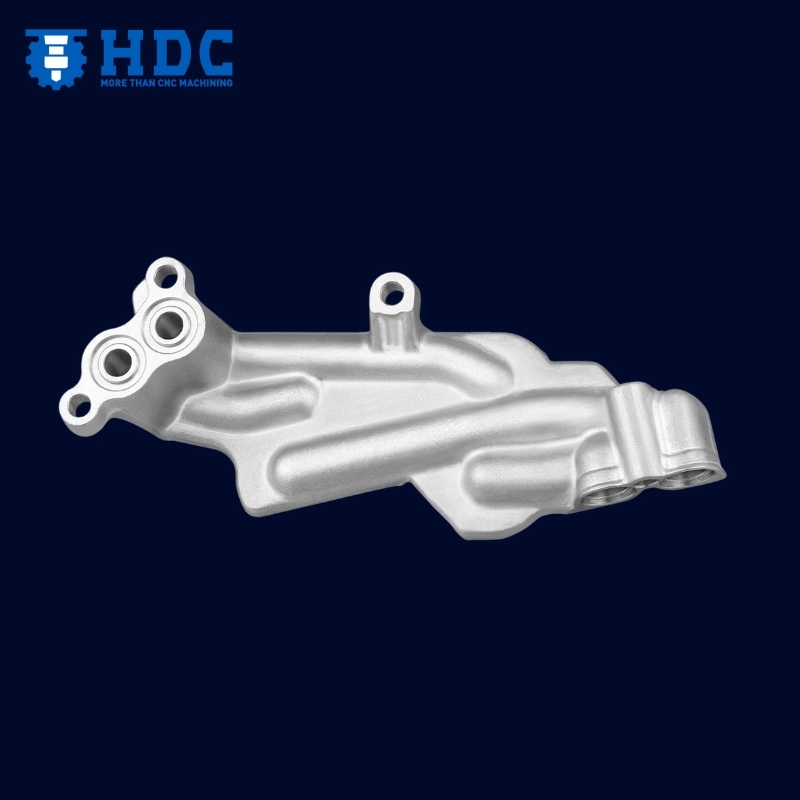

HDC Manufacturing has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your 416 stainless steel components to perfection, tailored to your specific requirements.

In the realm of precision engineering, HDC Manufacturing specializes in the intricate dance of 416 Stainless Steel Machining. Our adept team seamlessly intertwines avant-garde technology to guarantee a level of precision and efficiency that transcends conventional boundaries throughout every facet of the machining process. Whether navigating the complexities of intricate designs or overseeing the orchestration of large-scale productions, HDC Manufacturing possesses the acumen to meet the most exacting specifications with unwavering quality.

At the epicenter of our ethos lies an unyielding commitment to excellence and an incessant pursuit of innovation, solidifying HDC Manufacturing as the preeminent partner for all your 416 stainless steel machining imperatives. Embark with us on an odyssey of exploration, where the nexus of our seasoned experiential reservoir, cutting-edge technology, and steadfast dedication coalesce to ensure the actualization of your envisioned bespoke metal components. Choose HDC Manufacturing to immerse yourself in a tapestry of reliability, precision, and a manufacturing process that unfurls seamlessly.

What is 416 Stainless Steel?

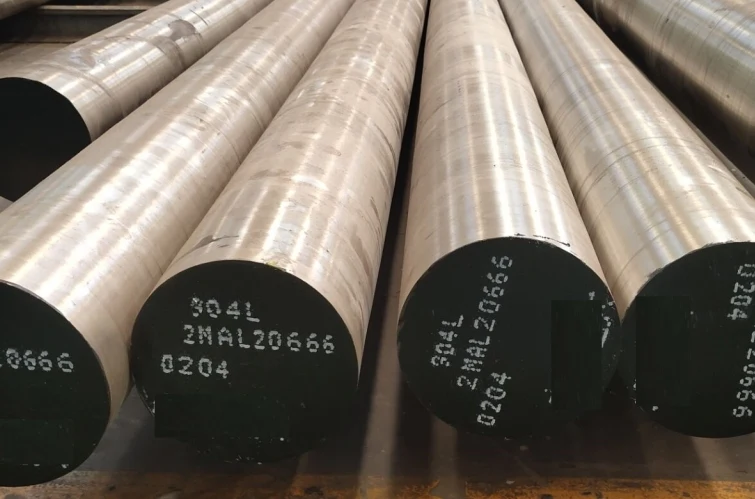

The 416 stainless steel is a marternstic grade in stainless steel, renowned for its great machinability, weather resistance and hardenability. It has approximately 13.5% of chromium mixed with a small amount of sulfur and manganese. By adding sulfur, 416 stainless steel improves workability, thus, drilling and machining become easier than for other stainless steels. This, however, also causes a sulfur content that can lead to reduced corrosion and weldability. This notwithstanding, 416 stainless steel is applied to industrial applications where good machinability and moderate corrosion resistance is necessary. For instance, it fits in the manufacture of components like nuts, bolts, shafts and valves. Also, it can thermally be processed to increase its mechanical properties and hardness which makes it easier to use it in different industries.

Characteristics of the 400 Series Stainless Steel

The 400 series stainless steels showing ferritic or martensitic to can be found classified by their microstructures and with chromium as the main alloying element, those with ferritic or martensitic to can be classified as having magnetic properties and have the properties of a good balance of strength, hardness, and resistance to corrosion. Though they possess generally lower corrosion resistance to the 300 series, some grades with higher chromium contend have adequate corrosion resistance that is sufficient for a particular use. They are infamous for high strength, hardness and used as wear resistant materials by baby gates, automotive, cutlery and industrial equipment. Although their inferior form-ability compared to austenitic stainless steels, they can be shaped and fabricated using proper techniques, making them versatile in various sectors.

What Limitations Does 416 Stainless Steel Have?

The 416 stainless steel not only has a very good machinability and moderate corrosion resistance, but is also characterised by several limitations. The corrosion resistance of this material is lower as compared with other grades of stainless steel, especially in very corrosive conditions. The presence of sulfur may create weldability issues, hence causing cracks and/or reducing the mechanical properties in the heat-affected zone during welding. The behavior of this material in cold forming tends to lead to work hardening and brittleness by the resistance to deformation. Furthermore, 416 SS in comparison to other grades suffers from poor toughness and has limited options for thermal heat treatment that can limit utilization of the alloy in applications where extra resistance to impact or dynamic loading needs to be present. This thus implies that these limitations should be carefully weighted when choosing materials for a specific application.

Chemical Composition of 416 Stainless Steel

| Component | Wt.% |

| Carbon (C) | 0..0 – 0.15 |

| Chromium (Cr) | 12.0 – 14.0 |

| Manganese (Mn) | 0.0 – 1.25 |

| Molybdenum | 0.0 – 0.6 |

| Phosphorus (P) | 0.0 – 0.06 |

| Silicon (Si) | 0.0 – 1.0 |

| Sulfur (S) | 0.0 – 0.15 |

| Iron (Fe) | Balance |

The Influence of Composition on the Properties of 416 Stainless Steel

The elements that determine stainless steel 416 composition and change its properties include the iron, chromium, sulfur, and small quantities of manganese and carbon. The high sulfur content improves machinability coupled with the chromium component that is responsible for corrosion resistance. Carbon affects hardness and strength by content. All these properties make the alloy machinable, has corrosion resistance, has hardness and strength. Although, 416 stainless steel has excellent machinability, moderate corrosion resistance, it has several limits like, poor weldability and corrosion resistance lower than other stainless steel grades, may be considered in materials selection as per requirement of specific applications.

Mechanical Properties of 416 Stainless Steel

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

| Annealed * | 517 | 276 | 30 | 262 | – |

| Condition T ** | 758 | 586 | 18 | 248-302 | – |

| 204 | 1340 | 1050 | 11 | 388 | 20 |

| 316 | 1350 | 1060 | 12 | 388 | 22 |

| 427 | 1405 | 1110 | 11 | 401 | # |

| 538 | 1000 | 795 | 13 | 321 | # |

| 593 | 840 | 705 | 19 | 248 | 27 |

| 650 | 750 | 575 | 20 | 223 | 38 |

| * Annealed properties are typical for Condition A of ASTM A582. | |||||

| ** Hardened and tempered Condition T of ASTM A582 – Brinell Hardness is a specified range, other properties are typical only. | |||||

| # Due to associated low impact resistance this steel should not be tempered in the range 400- | |||||

Physical Properties of 416 Stainless Steel

Density kg/m³ | Thermal Conductivity W/mK | Electrical Resistivity (Microhm/cm) | Modulus of Elasticity | Coefficient of Thermal Expansion µm/m/°C | Specific Heat (J/kg.K) | Specific Gravity |

| 7750 | 24.9 at 212°F | 43 at 68°F | 200 GPa | 9.9 at 32 – 212°F | 460 at 32°F to 212°F | 7.7 |

| 28.7 at 932 °F | 11.0 at 32 – 599°F | |||||

| 11.6 at 32-1000°F |

Equivalent Materials of 416 Stainless Steel

| EU | USA | France | England | Sweden |

| EN | – | AFNOR | BS | SS |

| X12CrS13 (1.4005) | 416 | Z11CF13 | 416S21 | 2380 |

How to Process 416 Stainless Steel?

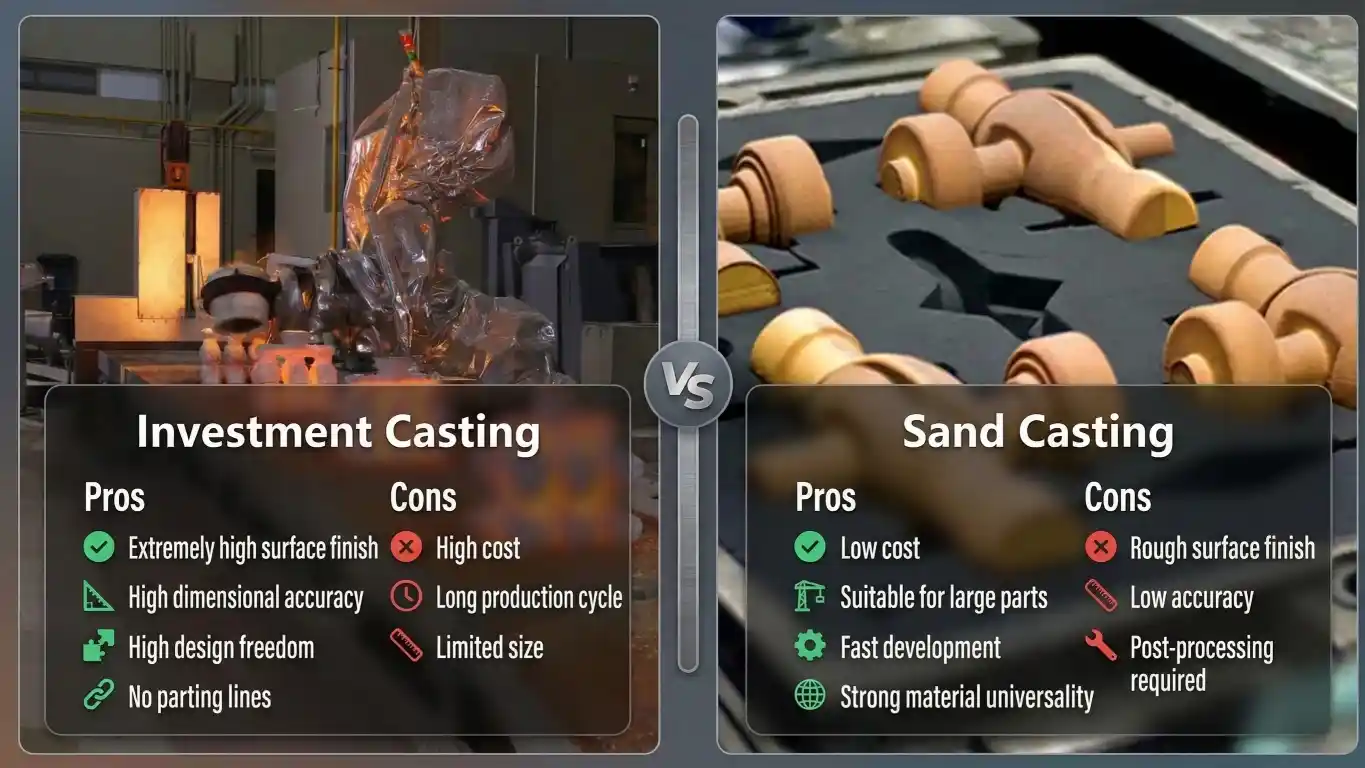

It is one and many techniques to be processed the 416 stainless steel. The alloy is renowned for its amazing properties of being machined easily and the machining operations which can be performed on it include use of conventional methods of machining such as turning, milling, drilling, and tapping. Heat treatment which consists of annealing for stress relief and improved machinability, as well as hardening and tempering for enhanced strength and hardness are also included and used based on specific mechanical property requirements. Although welding is commonly difficult because of the high sulfur it contains, it can be done by preheating and post-weld heat treatment operations to reduce the problems. Surface finishing techniques like grinding, polishing, and passivation are the most common way to get attractive looking finishes and corrosion resistance, while the cold working methods such as bending and drawing can create desired shapes. At last, proper techniques in operation ensure better fabricating of 416 stainless steel to meet application requirements.

Benefits of Using 416 Stainless Steel in Machining

As a martensitic chromium steel alloy, 416 stainless steel is generally referred to as the best free-machining stainless steel. With good corrosion and oxidation resistance plus high strength in hardened and tempered conditions, alloy 416 is mostly used for electrical motors, pumps, valves, nuts, bolts, gears, parts of automatic scew machines, and more.