Overview

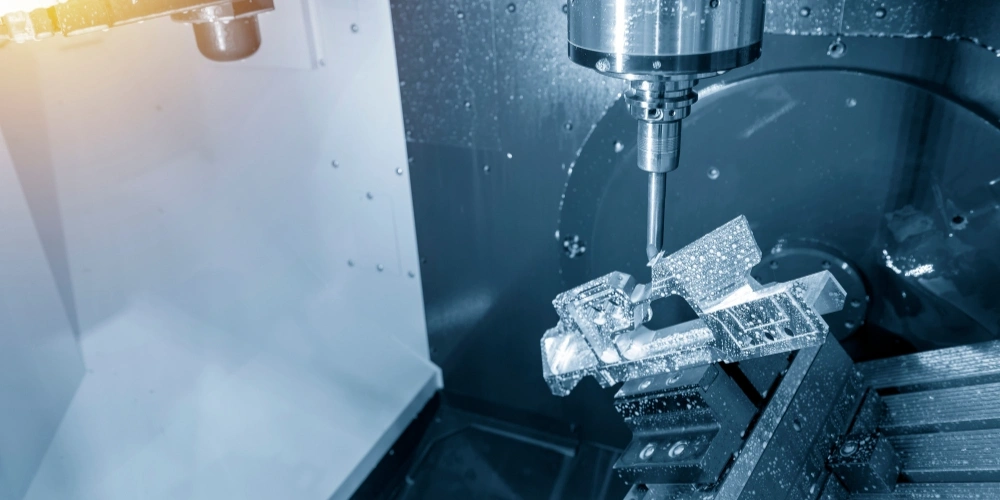

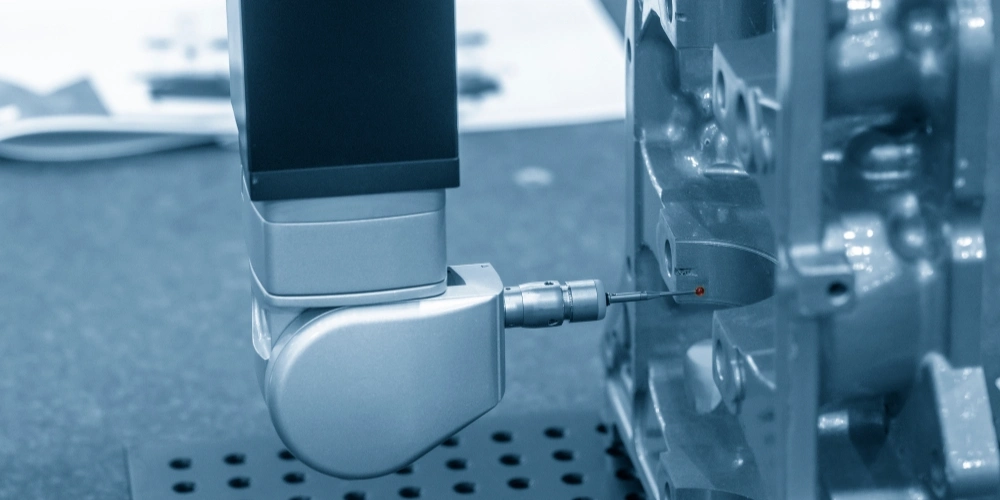

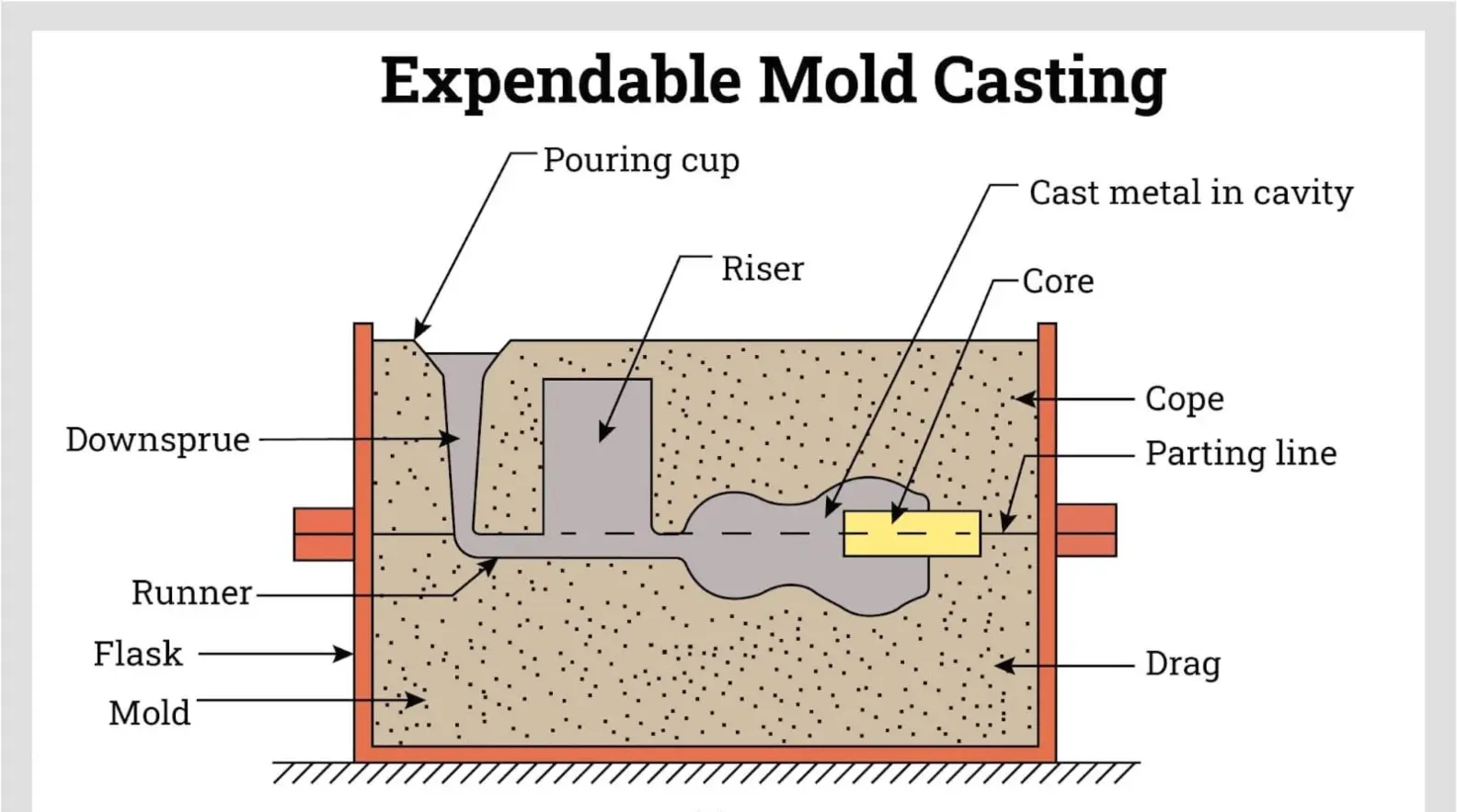

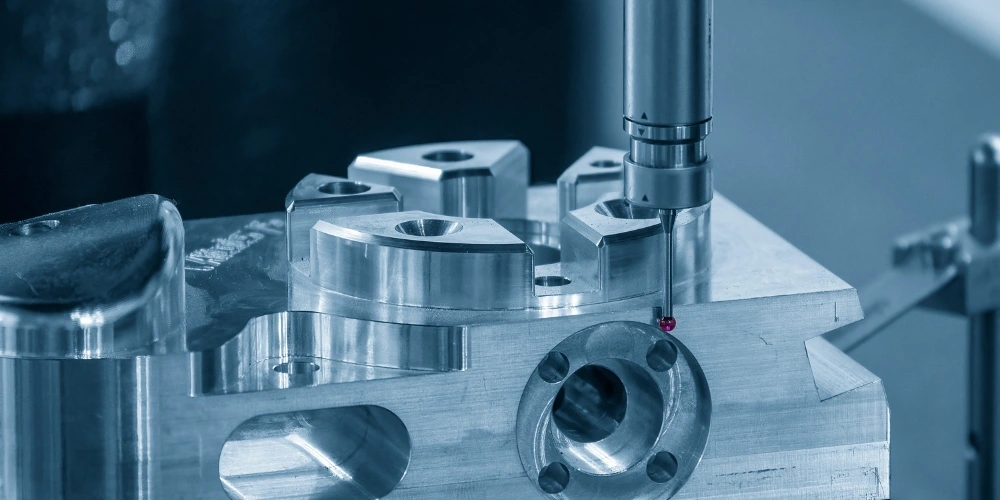

Welcome to HDC Manufacturing, your trusted partner with over a decade of expertise in crafting bespoke metal products. Our advanced production facilities feature 4-axis and 5-axis machining centers, alongside cutting-edge inspection tools like a coordinate measuring machine. HDC Manufacturing offers a diverse array of machining options, including CNC machining, casting, forging, laser cutting, and metal stamping.

Step into the realm of 5083 Aluminum Machining on our dedicated page, where we delve into the various parameters and applications of this exceptional material. Known for its exceptional corrosion resistance, high strength, and excellent weldability, 5083 Aluminum stands as a versatile alloy widely utilized in marine and aerospace applications. HDC Manufacturing stands out in 5083 Aluminum machining, harnessing advanced technology and years of experience to deliver superior capabilities. Our unwavering commitment to quality and precision positions HDC Manufacturing as the ideal partner for all your customized metal part needs.

Explore the HDC Manufacturing advantage – a convergence where innovation seamlessly intertwines with craftsmanship. Our expertise in 5083 Aluminum machining ensures top-notch results, precisely tailored to meet your specifications and industry standards.

What is Aluminum 5083?

The 5083 Aluminum is a high-strength alloy that is a mixture of aluminum, magnesium, and manganese as the main constituent. The material is classified under 5xxx series of aluminum alloys that offer superior corrosion resistance and weldability. Alloy 5083 is greatly appreciated for its outstanding performance in marine applications, which is a huge selling point for the marine industry and offshore structures. It is known for its excellent formability, machinability, and stiffness, and at the same time provides stress corrosion cracking resistance. Moreover, aluminum 5083 is employed in the manufacture of under carriages, tanks and large military vehicles that require a balance among high strength, resistance to corrosion and lightness.

What Are the Common Characteristics of Aluminum Alloys in the 5000 Series?

Aluminum alloys from the 5000 series, such as 5083 and 5052, typically exhibit similar traits that account for their wide range of uses in various applications. Epecifically, they provide exceptional corrosion resistance, especially in corrosive marine areas. Such alloys possess good strength, weldability, and formability dimensions, making various applications possible by fabricating them into different shapes and structures. Besides, they are easy to machine and can anodize successfully for better corrosion and aesthetical purposes. Since they possess high fatigue strengths, the 5000 series aluminum alloys are used in many industrial fields where a seemingly untradeable combination of strength, corrosion resistance, and fabrication versatility is required, which includes marine, aerospace, and automotive industries.

Chemical Composition of Aluminum 5083

Aluminum 5083, is highly resistant to industrial chemicals and seawater, so good choice for extreme environments, its common applications as vehicle bodies, marine industry, mine skips and cages.

Chemical Element | % Present |

| Manganese (Mn) | 0.40 – 1.00 |

Iron (Fe) | 0.0 – 0.40 |

| Magnesium (Mg) | 4.00 – 4.90 |

Silicon (Si) | 0.0 – 0.40 |

| Copper (Cu) | 0.0 – 0.10 |

Zinc (Zn) | 0.0 – 0.25 |

| Titanium (Ti) | 0.0 – 0.15 |

Chromium (Cr) | 0.05 – 0.25 |

| Other (Each) | 0.0 – 0.05 |

Others (Total) | 0.0 – 0.15 |

| Aluminium (Al) | Balance |

The Influence of Various Components on the Properties of Aluminum 5083

Alloy 5083 has different parts. These elements collectively determine its characteristics. Magnesium especially is a good solution because it has two advantages: it increases the strength and corrosion resistance which makes it suitable for offshore applications. Magnesium promotes refinement of grains and solid solution strengthening,ensuring enhanced mechanical properties and resistance to line cracks. As trace elements such as Fe, Si, Cu and Zn play a role in aspects like strength, ductility, and corrosion resistance, it is important to have controlled amounts in order to achieve desired properties while concentrations that are too high can give undesirable results. In addition to these, there are other mineral entities like titanium, chromium, and nickel that respectively have the roles of grain size control, precipitation hardening, and corrosion resistance. The boric acid controlled content of these components for the aluminum alloy 5083 provides the balance in properties, which makes it highly suitable for stringent industries, especially in marine and aerospace.

Can Aluminum 5083 Be Customized by Adjusting the Element Content?

Yes, aluminum alloy 5083 is customized with the amount of alloying elements changed to suit some particular conditions. For the composition of the alloy, magnesium, manganese and the concentrations of other elements like iron, silicon, copper and zinc can be adjusted to get the preferred properties such as strength, corrosion resistance, weldability and machinability. For instance, by a higher proportion of magnesium it becomes possible to achieve both a higher strength and corrosion resistance which makes it acceptable in marine applications. These elements are also able to be controlled to differentiate between their contents hence, they are used to enhance the properties by controlling specific things such as grain size control, precipitation hardening, and resistance to specific forms of corrosion. The manufacturers can determine the elements’ composition by using specific alloy formulation and through accurate manufacturing processes to meet the demands of different industries and applications.

Mechanical Properties of Aluminum 5083

Properties | Metric | Imperial |

Tensile strength | 317 MPa | 46000 psi |

Yield strength | 228 MPa | 33000 psi |

| Shear strength | 190 MPa | 27600 psi |

Fatigue strength | 159 MPa | 23000 psi |

| Shear modulus | 26.4 MPa | 3830 psi |

Elastic modulus | 71 GPa | 10300 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

Elongation at Break | 16% | 16% |

| Fracture Toughness | 43 MPa-m½ | 39.1 MPa-m½ |

Hardness, Brinell | 85 | 85 |

Physical Properties of Aluminum 5083

Density (kg/m3 ) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion 20-100°C (m/m/°C) | Thermal Cond Thermal Conductivity at 25°C (W/m.K) | Electrical Conductivity MS/m at 20°C | Electrical Resistivity (nΩ.m) | |

| Equal Volume | Equal Mass | |||||

2660 | 71 | 23.8 | 117 | 17 | 57 | 59 |

Equivalent materials of Aluminum 5083

UNS | ISO | BS | DIN | |

No | No | Name | ||

A95083 | AlMg4 .5Mn | N8 | 3.3547 | AlMg4 .5Mn |

What Processing Methods Are Suitable for Aluminum 5083?

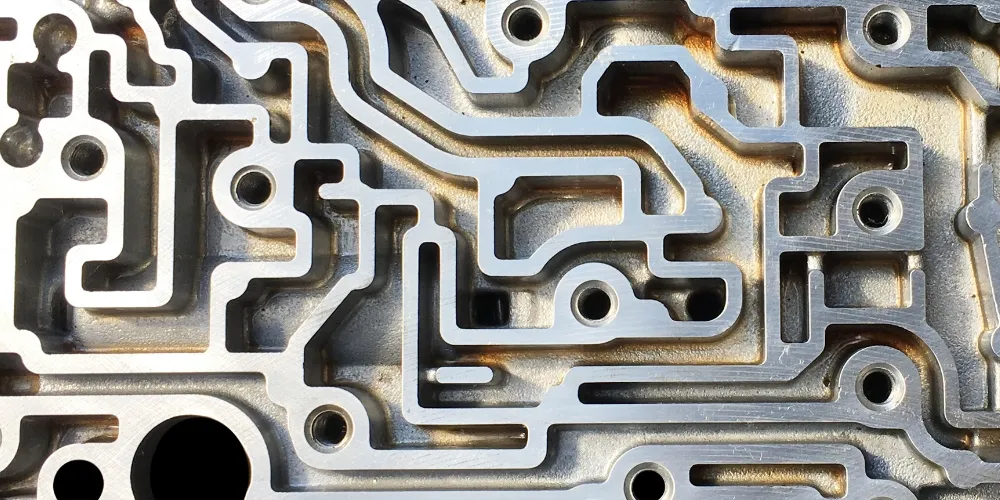

Various processing methods can be used for aluminum alloy 5083, as it is endowed with an array of versatile properties. Machining using conventional techniques, welding using several methods and forming through bending, stamping, or extrusion are some of the processing techniques that can be used. Besides, aluminum 5083 can be subjected to heat treatment with subsequent increase of its mechanical properties. Anodizing can be used in terms of corrosion resistance and decorative finishes. It offers compatibility with a wide range of processing methods, which renders it suitable for various industries like marine, aerospace, automotive and construction whereby it provides versatility in manufacturing and matching with diverse performance requirements.

Applications of Aluminum 5083

1. Automotive: 5083 Aluminum elevates automotive components—block guards, valve covers, shift knobs, and lightweight, durable wheels—ensuring top-notch performance and longevity on the road.

2. Aerospace: In aerospace, 5083 Aluminum’s lightweight and corrosion resistance are critical for structural elements, fuselage panels, and aircraft skins, providing essential strength and reliability for air travel.

3. Medical: Critical in the medical field, 5083 Aluminum is utilized for precision equipment and devices, offering biocompatibility, lightweight properties, and corrosion resistance for medical sensor housings, surgical instruments, and vital components.

4. Custom Products: Versatility defines 5083 Aluminum in custom products—weld-on hinges, piano hinges, barrel hinges, heavy-duty barrel hinges, and bullet hinges—ensuring durability and adaptability.

5. Motorcycle: 5083 Aluminum plays a pivotal role in motorcycles, contributing to triple clamps, billet wheels, motocross wheel sets, wheel hubs, radiator guards, bar ends, and footpegs for enhanced performance and aesthetics.

6. Trailer: Ensuring robustness in trailers, 5083 Aluminum features in spring pin latches, lashing rings, pintle hooks, trailer jacks, and ramps, providing reliability in challenging trailer conditions.

7. Bicycle: Lightweight and durable, 5083 Aluminum is favored in the bicycle industry, enhancing the performance and longevity of bike stems, chainrings, bicycle hubs, pedals, and cranksets.

8. Kart: In kart manufacturing, 5083 Aluminum’s strength and resilience shine in components—sprockets, washers and spacers, wheel hubs, steering wheels, and wheel rims—meeting the high-performance standards required in karting.