The Ultimate Guide to Steel Turned Parts: Types, Applications, and CNC Machining

Discover everything you need to know about steel turned parts, from understanding the machining process and types of steel used to their applications across various industries. Learn about the benefits of CNC turning, challenges faced, and tips for selecting the right manufacturer.

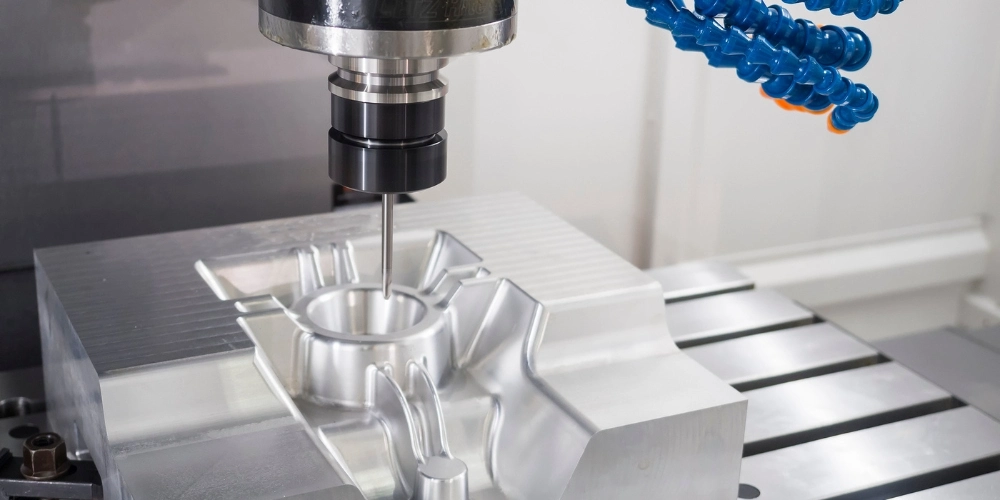

Understanding Steel Turned Parts

Figure 1 – Stainless steel turned parts

It’s pretty self-explanatory, especially if you have experience in the machining and industrial field. However, for the benefit of everyone, let me briefly discuss what steel turned parts are.

From its term, these are materials made from steel that have undergone the process of “turning” to be able to produce the part or component. Turning is the process of mounting a workpiece or material onto a lathe, and the workpiece or material is abruptly turned while being bumped into a cutting tool.

Steel turned parts are exceptionally known in the industrial sector to the extent that they’re seen in many different business industries. Bringing us to the next question, which is…?

Characteristics of CNC Turned Parts

CNC (Computer Numerical Control) turning is an efficient way of manufacturing cylindrical shapes involving spinning bars on a chuck and using cutting tools to remove material, leading to the desired form. This method is capable of creating round, or cylindrical shapes with rotational symmetry and internal features such as holes bore ,and threads. This process provides the tight control of surface finish required for smooth finishes and may be capable to matching given tolerances due regard on machine capabilities as well as part geometry. Due to its rotational nature, symmetry is formed around the axis of rotation in parts produced unlike with asymmetrical features that are hard created. Furthermore, CNC lathes are able to make complicated profiles contours fillets and chamfers. But the dimensions of geometrically cut parts depend on a lathe’s capacities and larger lathes can handle bigger components effectively. Secondly, the strengths of CNC turning include being able to produce both outside and inside threads which are accurate thus making this technique vital not only in one industry but several applications.

Apply Industries of Steel Turned Parts

Figure 2 – A steel-turned part in the automotive sector

Figure 2 – A steel-turned part in the automotive sector

- Machineries and Industrial Equipment Industries

- Automotive and Aerospace Industries

- Marine and Maritime Industries

- Shipyard and Shipbuilding Industries

- Electronics and Technology Sectors

- Heating, Ventilation, and Air-Conditioning (HVAC) Industries

- Medical and Pharmaceutical Industries

- And Many More!

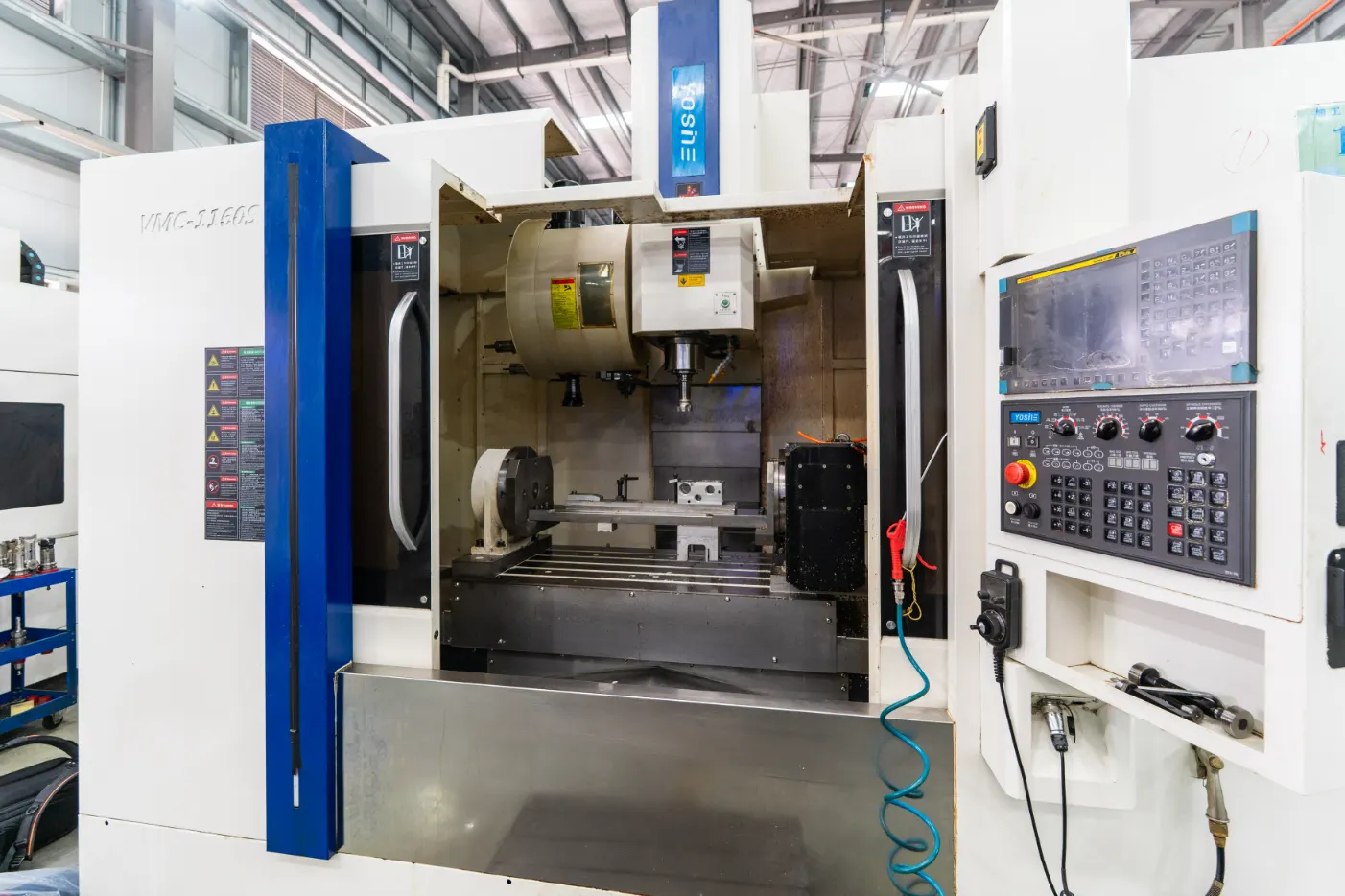

Understanding CNC Precision Machining

These are parts or components made via the process of computer numerically-controlled machines and equipment. In simpler terms, these are manufacturing methodologies done that are computer aided and assisted, and usually do not require human interference or intervention.

Of course, the process would be turning or when the material or workpiece is held and mounted onto the machine and spun while a cutting tool is applied onto it to reduce or to subtract material from it.

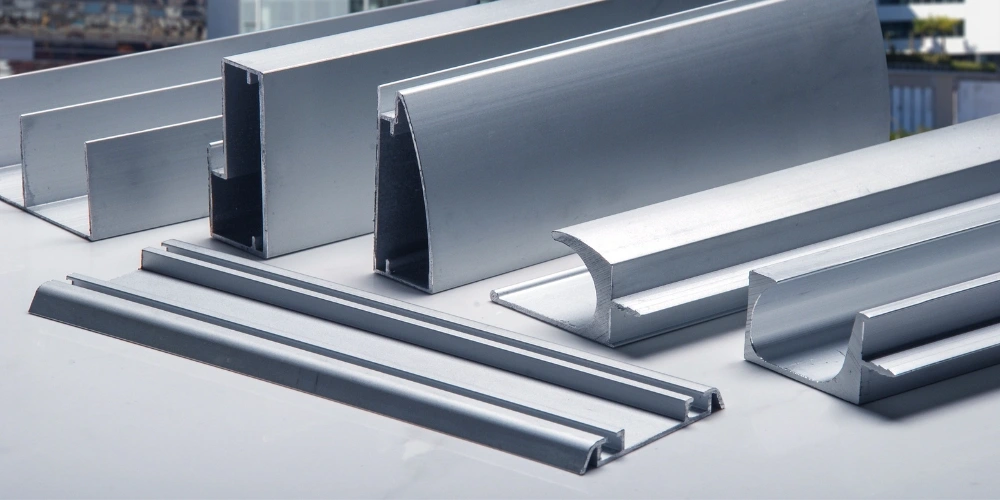

Types of Steel Used in CNC Turning

Figure 3 – An alloy bar, considered as one of the most commonly used types of steel in turning

Steel turning is a vague term, as a matter of fact, it’s one of the terms that can still be further narrowed down to help identify and determine the type of end result better and more specified.

To start off, there is a wide variety of steel types that you can use for steel turning parts and components of various machines and equipment, these steels are:

Alloy Steel

This is the specific type of steel that’s made with one or more metal other than iron.

Carbon Steel

Just because they’re labelled as “carbon” steel doesn’t mean they’re 100% made of carbon. Carbon steel has varying levels of carbon, but, in general, carbon steel has higher levels of carbon, making them stronger, more durable, but more brittle.

Stainless Steel

Stainless steel is one of the rarest and most unique types of steel as it contains around 10 to 20 percent chromium, making its corrosion and abrasion resistance higher and more noticeable. Stainless steel, in case you’re not aware, is the type of steel commonly used for outdoor enclosures and those that are exposed to nature.

Tool Steel

Last but most definitely not least is tool steel. They’re named as one of the most durable and heat-resistant types of metal as they contain vanadium, cobalt, tungsten, and molybdenum. This combination of alloys makes them strong and applicable for various applications such as for drill bits, and other tools, hence the term “tool steel.”

These are the different types of steel that are the most commonly used for the production of steel turned parts and components. Do note, though, that these are the general categorizations and specifications of steel and they are not limited and restricted to these.

The Best Steel For Turning

Figure 4 – Stainless steel turned parts

Out of all the different types of steel, experts and manufacturers consider stainless steel as the best and most machinable type of steel due to the range it has in terms of flexibility, versatility, adaptability, and more.

They also have excellent properties in terms of strength and resistance, and they have superior weldability and formability properties that are important for various applications.

Mild Steel Used in CNC Turning

Figure 5 – A mild steel-turned component

Yes, akin to all other types of steel, mild steel can be tuned. However, a problem concerning the process of machining mild steel is at hand. This problem revolves around their malleability property – they’re too soft and they have a gel or “gummy” like consistency, making it difficult and challenging to maintain the form, especially during turning.

Nevertheless, with the right skills, tools, and procedures, mild steel can easily be turned and machined.

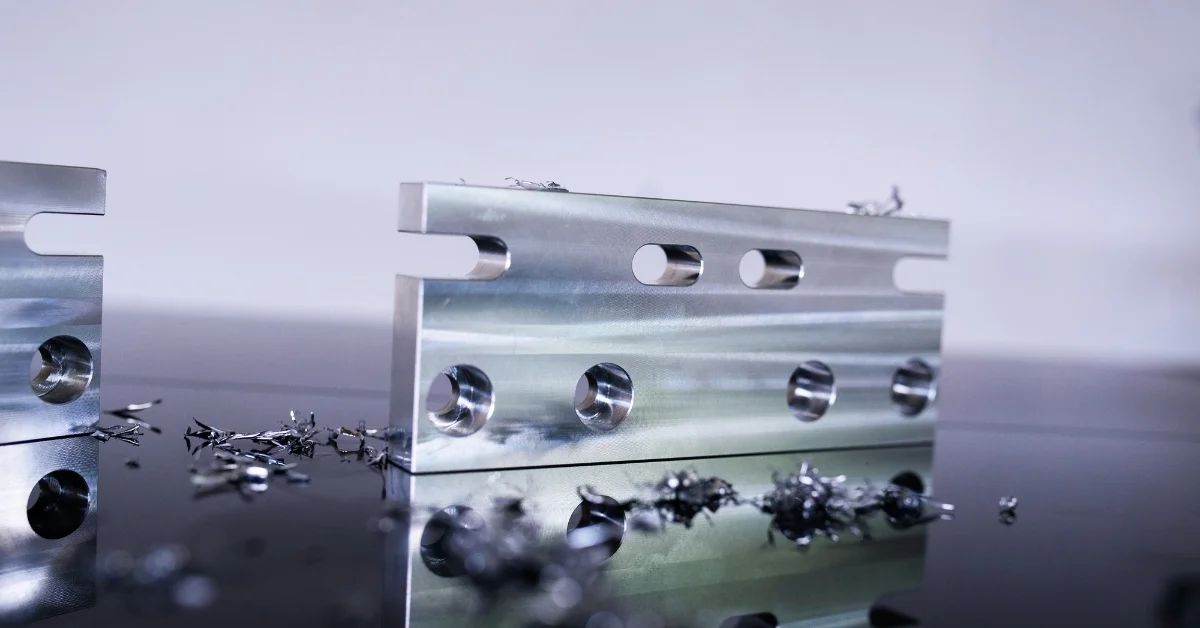

Tolerances Can be Achieved With Steel Turned Parts

In CNC turning, steel turned parts generally achieve the following tolerances: ±0.001 to ± 5 inches (24 microns – 139 micrometers). But the particular tangible tolerance that is possible will be influenced by various factors such as machining capabilities of CNC machine, quality level of tooling materials properties part geometry and environmental qualifications. These elements combined ultimately define the specific tolerances that can be obtained with standard props for steel turned components.

Surface Finishes Can be Applied to Steel Turned Parts

- Smooth or Polished Finish: This finish produces a very smooth and mirror-like surface that is great for low friction requirements, where some sort of not extremely rough appearance is needed.

- Brushed Finish: The brushed finish delivers fine parallel lines on the steel surface which provide aesthetic look and touch.

- Bead Blasted Finish: Bead blasting is the process of jetting abrasive particles on steel object surfaces and creating a matte uniform texture that can be used to reduce glare, thus improving grip.

- Anodizing: Mostly useful for aluminum, anodizing can have steel applied to enhance the corrosion resistantability and provide a variety of color options.

- Plating: Steel components can be plated with other materials such as chrome, nickel or zinc to improve their appearance and increase resistance.

- Painting or Powder Coating: These finishes provide colour and protection on the steel surface it offers comprehensive aesthetic choices.

- Electropolishing: This operation produces smoother and brighter surfaces that result in better corrosion resistance, as well as a more attractive appearance.

Challenges in CNC Turning with Steel

Tool wear, heat generation vibrations and material variation are some challenges involved when using CNC turning with steel. Level of hardness in steel requires frequent tool changes, plus efficient cooling while reducing vibration and chatter needs machine stability as well matching criteria for feeds speeds and depth of cuts. It is also of great importance to understand the steel grades; chip control strategies are required because sharp chips. Some geometries could require several sites, and workpieces’ securing is critical. Also the costs of quality steel, tooling and maintenance can influence utility. Even in the face of such difficulties, steel CNC turning continues to be a desirable approach for producing high-precision products that are demanded by many industries.

Tool wear, heat generation vibrations and material variation are some challenges involved when using CNC turning with steel. Level of hardness in steel requires frequent tool changes, plus efficient cooling while reducing vibration and chatter needs machine stability as well matching criteria for feeds speeds and depth of cuts. It is also of great importance to understand the steel grades; chip control strategies are required because sharp chips. Some geometries could require several sites, and workpieces’ securing is critical. Also the costs of quality steel, tooling and maintenance can influence utility. Even in the face of such difficulties, steel CNC turning continues to be a desirable approach for producing high-precision products that are demanded by many industries.

Guidance for Custom CNC Turned Parts

When procuring CNC turned custom parts, manufacturers must ensure that the process is streamlined corporately. First, state your project requirements in a clear manner you need to provide the details of material type dimensions tolerances, and surface finish. Then, decide on a reliable supplier that can provide top-notch CNC turning services and offer precision stringency.

Obtain three quotes from manufacturers using a more detailed drawing or CAD file for precision. Compare quotes with method of price, lead times and capabilities. Select materials with the manufacturer through other considerations such as strength and corrosion resistance.

Provide your needed tolerances and specified finish, along with requesting for the quality control procedures utilized by this particular manufacturer. Raise the issue of production lead times and shipping methods to match your project calendar. During the project, there should be constant communication with an emphasis on submitting prototypes or samples if possible.

State pricing details, payment terms including other costs in advance; identify shipping methods and packaging that meet your needs for a safe passage of custom turned parts. On receiving these parts, carry out checks to ensure that the items match your specifications. Such steps will bring order out of chaos and lead to a successful production run for your CNC turned parts.

Steel Turned Parts Manufacturer You Can Trust

Out of the multitude of steel turned parts manufacturers and suppliers you have ever come across or encountered in the market, have you found one as great as us here at HDC Manufacturing? Being in the industry for more than a decade, we have been hailed as China’s most trusted manufacturer of steel turned parts for various types of components.

We have been the best in terms of machining stainless steel turned parts, spare machine parts, casting steel turned parts, nuts and bolts, screw nuts, and many more!

So, if you have questions or inquiries – or if you are interested to work with us, send us a message and upload a draft of the product you want produced, and we will send you a free quotation!

Other Products HDC Known For

Other than our name of being the best steel turned parts manufacturer, we’re also known in the industry for our laser cutting services, 5-Axis Machining, aluminum forging, as well as our manufacturing of CNC auto and motorcycle parts, too!

Don’t ever think that our services are limited to just steel turned parts – that’s just the tip of the iceberg!

Conclusion

To get steel turned parts, the knowledge about machining process, types of steels available to us for making such items is extremely important as well as tolerances and surface finishes. HDC Manufacturing has been in business for more than a decade and offers reliable partnerships through their production of various components such as stainless steel turned parts casting, and steels link. This covers areas such as, laser cutting technology 5-Axis Machining aluminum forging and CNC auto motorcycle parts manufacturing. For your custom machining, reach HDC Manufacturing.