What is 1215 Carbon Steel?

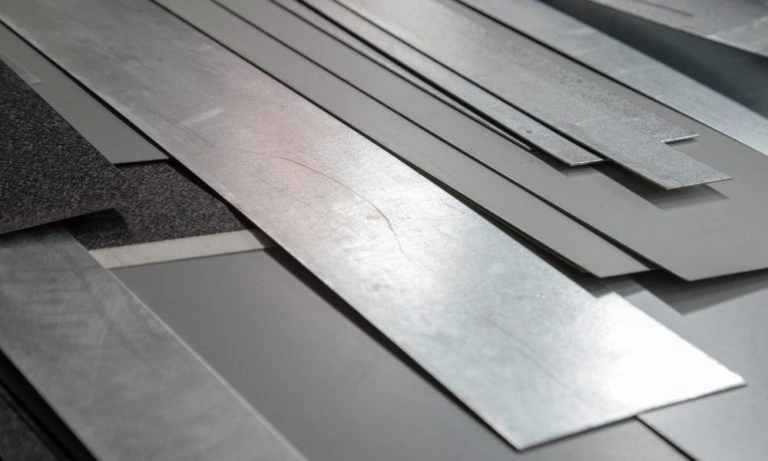

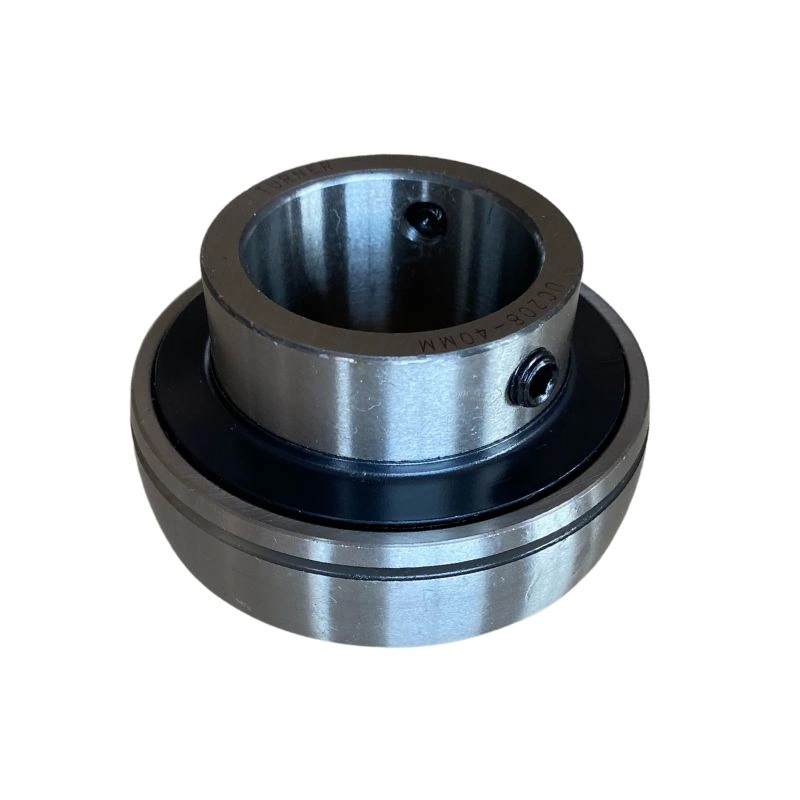

1215 carbon steel that is also called resulfurized carbon steel is a free-machining steel possessing the higher sulfur percentage than standard carbon steels. The improved sulfur content can offer better machinability through the formation of ferric and manganese sulfides, which will act as chip breakers during machining operations. Such constitutes higher productivity, less wear and tear of the tool, and a smoother surface finish as compared with the other carbon steels. The 1215 steel is one in the most common used materials for parts which requires complex machining, including bolts, screws, bushings and fittings, where the dimensions and the surface finish of the component are critical. On the other hand, its low carbon content gives it soft ductility, weldability, and formability thus making it strive well in many fabrication processes.

How Is 1215 Carbon Steel Named?

The 1215 carbon steel follows the AISI four-digit system. The first digit “1” indicates carbon steel, while the “15” represents a carbon content of about 0.15% by weight. Unlike other steels, 1215 doesn’t focus on secondary alloying elements but on its enhanced machinability, thanks to added sulfur. This naming system highlights its low carbon content and optimized machining properties, making 1215 ideal for parts requiring extensive machining.

How Are Base Carbon Steel Grades Classified?

Carbon steel grades are classified by their carbon content. Low carbon steels (up to 0.3% carbon) offer ductility and weldability, medium carbon steels (0.3% to 0.6%) balance strength and flexibility, and high carbon steels (0.6% to 1.0%) provide superior strength and wear resistance. The AISI/SAE system uses a four-digit code, with the first two digits (“10” for plain carbon, “11” for sulfur/phosphorus-added) indicating composition, and the last two digits showing carbon content as a percentage. This system simplifies understanding steel properties for various applications.

What Are the Advantages and Disadvantages of 1215 Carbon Steel?

1215 carbon steel offers exceptional machinability at a competitive price, thanks to its added sulfur that enhances chip breaking during machining. This results in improved surface finishes and extended tool life. Its free-cutting nature makes it ideal for precise and intricate machining processes. However, its low strength and ductility limit its use in high-stress applications or operations requiring higher strength. The sulfur content can also compromise weldability, necessitating special precautions during welding. Despite these drawbacks, 1215 carbon steel remains a valuable material in industries where ease of machinability and affordability are key considerations.

1215 Carbon Steel Chemical Composition

1215 Carbon steel is a low-alloy, fast cutting steel, widely recognized as the standard screw stock. As a standard resulfurized and rephosphorized carbon steel, it is generally designed for screw machining such as bushings, inserts, knives, hammers, saws couplings, studs, pins, and other tools, due to its benefits of excellent cutting speeds and machining properties, like high toughness, good toughness, wear resistance, and formability.

| Component | Wt.% |

| Carbon (C) | 0.0 – 0.09 |

| Manganese (Mn) | 0.75 – 1.05 |

| Phosphorus (P) | 0.04 – 0.09 |

| Sulfur (S) | 0.26 – 0.35 |

| Iron (Fe) | Balance |

The Influence of Various Elements on the Properties of 1215 Carbon Steel

The properties of 1215 carbon steel are influenced by its carbon, manganese, sulfur, phosphorus, silicon, and trace element content. Carbon affects hardness and machinability, manganese refines grain and enhances mechanical properties, sulfur aids machinability but can reduce ductility, and phosphorus may improve machinability or induce brittleness. Silicon acts as a deoxidizer and enhances strength, while trace elements impact corrosion resistance and mechanical strength, allowing for tailored properties in various applications.

1215 Carbon Steel Mechanical Properties

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 540 MPa | 78300 psi |

| Tensile Yield Strength | 415 MPa | 60000 psi |

| Elongation at Break | 10 % | 10 % |

| Reduction of Area | 35 % | 35 % |

| 1215 Steel Hardness, Brinell | 167 | 167 |

| 1215 Steel Hardness, Knoop | 188 | 188 |

| 1215 Steel Hardness, Rockwell B | 85 | 85 |

| 1215 Steel Hardness, Vickers | 175 | 175 |

| Modulus of Elasticity | 200 GPa | 29000 ksi |

| Bulk Modulus | 160 GPa | 23200 ksi |

| Shear Modulus | 80.0 GPa | 11600 ksi |

| Poissons Ratio | 0.29 | 0.29 |

1215 Carbon Steel Physical Properties

| Physical Properties | Metric | English | Comments |

| Density | 7.87 g/cc | 0.284 lb/in² | |

| Electrical Properties | |||

| Electrical Resistivity | 0.0000174 ohm-cm | 0.0000174 ohm-cm | Typical steel |

| Thermal Properties | |||

| Specific Heat Capacity | 0.472 J/g-°C | 0.113 BTU/lb-°F | Typical steel |

| Thermal Conductivity | 51.9 W/m-K | 360 BTU-in/hr-ft²-°F | Typical steel |

1215 Carbon Steel Equivalent Materials

| USA | AISI | AISI 1213 AISI 12L13 AISI 12L14 | ||||||||||

| SAE | SAE 1213 SAE 1215 SAE 12L13 SAE 12L14 | |||||||||||

| Germany | DIN,WNr | DIN 1.0715 DIN 9SMn28 DIN 11SMn30 DIN 1.0718 DIN 9SMnPb28 DIN 11SMnPb30 DIN 1.0736 DIN 9SMn36 DIN 11SMn37 | ||||||||||

| Japan | JIS | JIS SUM22 JIS 11SMn28 JIS SUM23 JIS SUM22L JIS SUM23L JIS SUM24L JIS 11SMnPb28 JIS SUM25 JIS 12SMn35 | ||||||||||

| France | AFNOR | AFNOR S250 AFNOR 11SMn30 AFNOR S250Pb AFNOR 11SMnPb30 AFNOR 11SMn37 AFNOR S300 | ||||||||||

| England | BS | BS 230M07 BS 11SMN30 BS 220M07 BS 11SMnPb30 BS 11SMn37 | ||||||||||

| Italy | UNI | UNI CF9SMn28 UNI 9SMn23 UNI CF9SMnPb28 | ||||||||||

| Spain | UNE | UNE 11SMn28 UNE 11SMnPb28 | ||||||||||

| China | GB | GB/T U71152 GB/T Y15 GB/T U72152 GB/T Y15Pb | ||||||||||

| Sweden | SS | SS 1912 SS 1914 | ||||||||||

| Inter | ISO | ISO 11SMn28 ISO 11SMn30 ISO 11SMnPb30 ISO 11SMnPb28 ISO 12SMn35 ISO 11SMn37 | ||||||||||

| UNS | UNS G12130 UNS G12150 UNS G12144 UNS G12134 | |||||||||||

| ASTM | ASTM A29 Grade 1215 ASTM A29 Grade 12L15 ASTM A510 Grade 12L15 ASTM A510 Grade G12150 ASTM A519 Grade 1215 ASTM A576 Grade G12150 ASTM A738 Grade E ASTM A29 Grade 12L14 ASTM A510 Grade 12L14 ASTM A519 Grade 12L14 ASTM A576 Grade 12L14 | |||||||||||

How Is 1215 Carbon Steel Processed?

When it comes to processing 1215 carbon steel, machining is where it truly shines. The high sulfur content forms manganese sulfide inclusions, making chip breaking a breeze. Whether you’re turning, drilling, milling, or tapping, this steel handles complex and precise cuts like a champ.

If you need to tweak its mechanical properties or enhance the surface finish, cold working techniques like cold drawing or cold rolling do the trick. Heat treatments, especially stress relieving, help reduce internal stresses and keep everything dimensionally stable. You can also jazz it up with various surface finishes, coatings, or plating to boost corrosion resistance, increase surface hardness, or simply improve its visual appeal. This versatility is why 1215 steel finds its way into so many different applications.

What Challenges Are Encountered in Processing 1215 Carbon Steel?

Compared to higher carbon steels, 1215 is lower in strength and more prone to brittleness, which limits its use in high-stress applications. The sulfur content doesn’t do any favors for weldability either—you’ll need specialized techniques to avoid weld defects.

Achieving a good surface finish is usually possible with normalized 1215 steel, but you’ll need to pay close attention to machining parameters and tool selection to prevent surface imperfections. Overcoming these challenges is key to ensuring your final product is high-quality and performs well.

Common Applications of 1215 Carbon Steel

| Automotive | Motorcycle Parts | Trailer Parts | Bicycle Parts | Go Kart Parts |

| Wheel Spacer | Sprocket | Coupler | Bike Stem | Go Kart Spacer |

| Block Guard | Motorcycle Wheels | Trailer Jack | Wheel Hub | Go Kart Steering Wheel |

| Valve Cover | Wheel Hub | Receiver Tube | Crankset | Sprocket |

| Intake Flange | Radiator Guard | Trailer Paddle Lock | Bike Wheels | Wheel Hub |

| Wheel Lug Nut | Footpeg | Pintle Hook | ||

| Shift Knob | Triple Clamp | Ball Mount | ||

| Screws | Bar End |

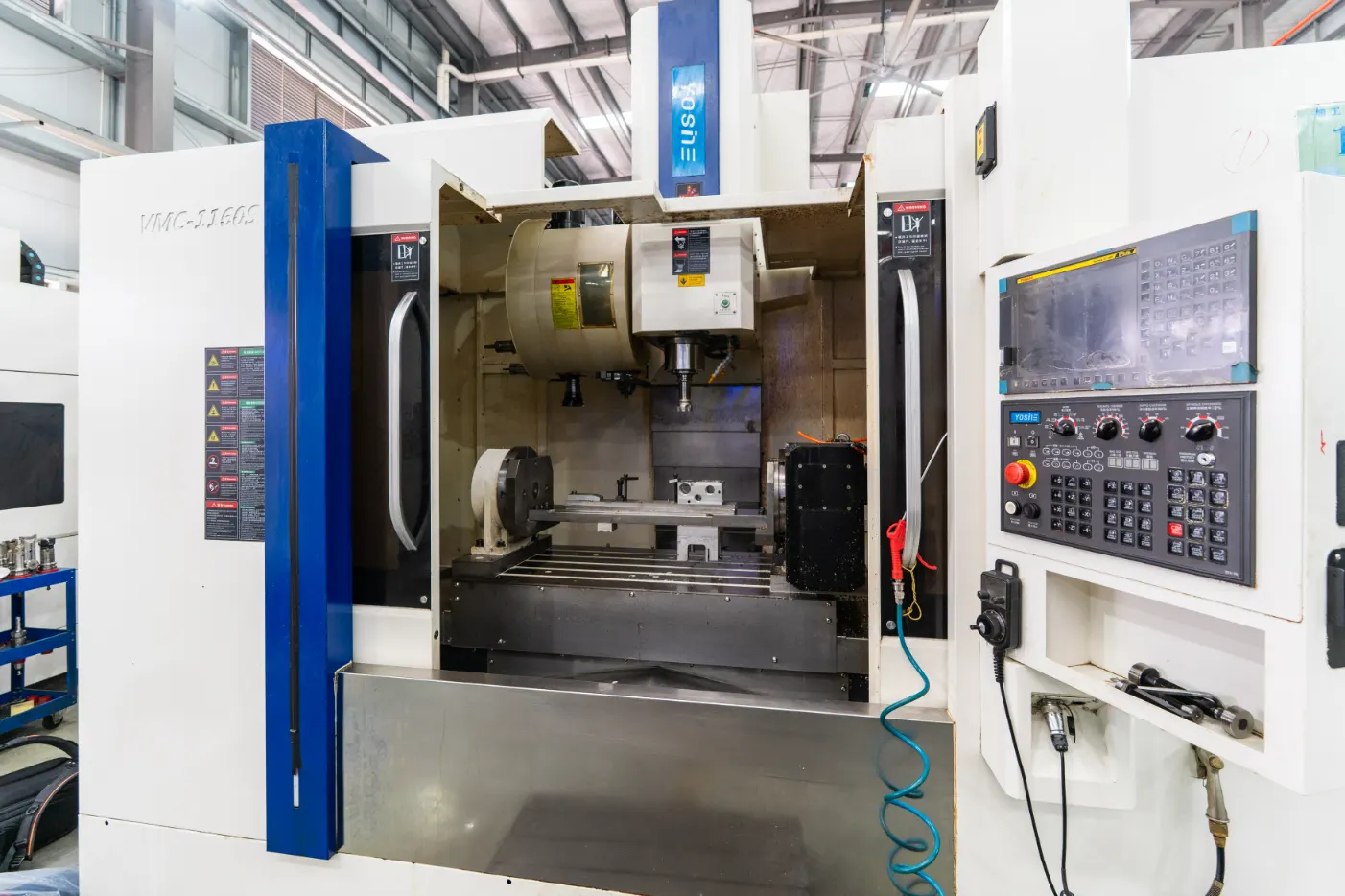

Understanding HDC's Precision Machining Capabilities

HDC possesses advanced machining technology, enabling us to provide custom 1215 carbon steel products for our customers. Our precision machining equipment and professional team ensure that every product meets the highest quality standards and fulfills your specific requirements.