Overview

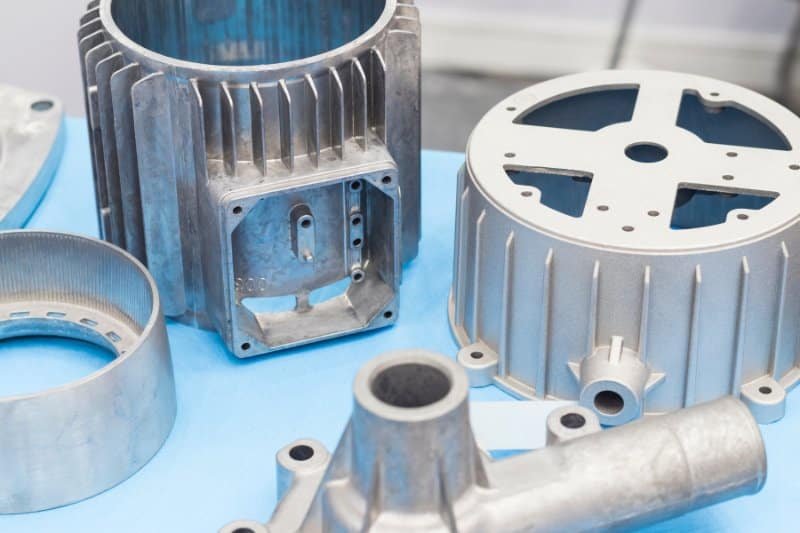

Embark on a journey with HDC, your esteemed collaborator in the realm of metal machining parts! Boasting over a decade of mastery in crafting custom metal parts, HDC showcases cutting-edge manufacturing facilities, encompassing 4-axis and 5-axis machining hubs, along with state-of-the-art inspection apparatus such as coordinate measuring machines. Our unwavering dedication to perfection empowers us to present an array of intricate processing alternatives, spanning CNC machining, casting, forging, laser cutting, and metal stamping.

Within HDC, we take immense pride in our distinctive proficiencies concerning 410 stainless steel casting. Our adept team harnesses their extensive acumen and technical prowess to yield exactitude and excellence in every casting endeavor. Be it intricate components or robust industrial elements, HDC is committed to addressing your precise 410 stainless steel casting requisites with unparalleled proficiency and efficacy.

Embark on an odyssey of possibilities with HDC as your ally in metal components, where our emphasis on 410 stainless steel casting distinguishes us. Entrust us with transforming your concepts into reality with meticulousness, dependability, and a dedication to excellence that defines HDC’s standing in the industry.

410 Stainless Steel Casting

410 Stainless Steel, often referred to simply as 410SS, is a versatile and corrosion-resistant alloy. It belongs to the martensitic family of stainless steels and is primarily composed of iron, chromium, and carbon. Its unique chemical composition imparts remarkable properties that make it a top choice for various casting applications, these remarkable properties include:

- Corrosion Resistance: One of the standout features of 410SS is its exceptional resistance to corrosion. This makes it an ideal choice for applications exposed to harsh environments, such as marine or chemical industries.

- High Strength: 410SS exhibits impressive tensile and yield strength, making it suitable for components subjected to heavy loads and stress.

- Heat Resistance: With the ability to withstand elevated temperatures, 410SS is a reliable choice for applications that involve high-temperature environments like exhaust systems and industrial ovens.

- Machinability: This steel alloy can be easily machined, providing manufacturers with flexibility in the design and production process.

- Wear Resistance: The inclusion of carbon in 410SS enhances its wear resistance, ensuring that components maintain their integrity over extended periods of use.

In conclusion, 410 Stainless Steel (410SS) is a remarkable alloy that has revolutionized the world of casting. Its impressive combination of corrosion resistance, high strength, heat resistance, and machinability makes it an invaluable material in various industries. Whether you’re in automotive, aerospace, oil and gas, medical, or food processing, 410SS can elevate the performance and longevity of your cast components.

Video of Stainless Steel Investment Casting

Frequently Asked Questions (FAQ) – 410 Stainless Steel Casting

In the world of metallurgy, 410 Stainless Steel (410SS) stands as a versatile and widely-used material known for its exceptional properties. From its chemical composition to its applications and unique advantages, this article will delve into the intricate details of 410SS, helping you understand its significance in various industries. We aim to provide you with a comprehensive FAQ that not only answers common queries but also positions this article as a valuable resource in the realm of 410SS knowledge.

What is 410 Stainless Steel (410SS)?

410 Stainless Steel, denoted as 410SS, is a type of martensitic stainless steel. It is alloyed with chromium, which imparts remarkable corrosion resistance to this material. Additionally, 410SS contains a moderate amount of carbon, which contributes to its strength and hardness. This combination of attributes makes it an exceptional choice for a wide range of applications.

What is the Chemical Composition of 410SS?

The chemical composition of 410SS is a critical factor in determining its properties. Here are composition ranges of grade 410 stainless steel.

Grade |

| C | Mn | Si | P | S | Cr | Ni |

410 | min. | – | – | – | – | – | 11.5 | 0.75 |

max. | 0.15 | 1 | 1 | 0.04 | 0.03 | 13.5 |

What are the Key Properties of 410SS?

Mechanical Properties

The following table displays the typical mechanical properties of 410SS:

Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50 mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

Annealed * | 480 min | 275 min | 16 min | – | – |

204 | 1475 | 1005 | 11 | 400 | 30 |

316 | 1470 | 961 | 18 | 400 | 36 |

427 | 1340 | 920 | 18.5 | 405 | # |

538 | 985 | 730 | 16 | 321 | # |

593 | 870 | 675 | 20 | 255 | 39 |

650 | 300 | 270 | 29.5 | 225 | 80 |

Physical Properties

Here are the basic physical properties of 410SS, including density, coefficient of thermal expansion, thermal conductivity, and so on.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100 °C (J/kg.K) | Electrical Resistivity (nΩ.m) | |||

| 410 | 7800 | 200 | 0-100 °C | 0-315 °C | 0-538 °C | at 100 °C | at 500 °C | 460 | 570 |

| 9.9 | 11 | 11.5 | 24.9 | 28.7 | |||||

Corrosion Resistance

Grade 410 stainless steel boasts resistance to high temperatures, steam, various foodstuffs, mild acids, alkaline solutions, fresh water, and arid atmospheres. These alloys achieve exceptional corrosion and heat resistance through a rigorous strengthening process. However, it’s crucial to note that they exhibit lower corrosion resistance compared to their austenitic counterparts and grade 430 ferritic alloys containing 17% chromium. The application of a polished surface finish significantly enhances their performance.

Heat Resistance

410 stainless steels have good scaling resistance at temperatures of up to 650 °C. However, the mechanical properties of the material will tend to reduce at temperatures ranging from 400 to 580 °C.

Heat Treatment

Annealing – 410 stainless steels can be fully annealed at temperatures from 815 to 900 °C, followed by slow furnace cooling and air-cooling. Process annealing of grade 410 steels can be carried out at temperatures ranging from 650 to 760 °C and air-cooled.

Hardening – Hardening of 410 stainless steels can be performed at 925 to 1010 °C, followed by air and oil quenching. Heavy sections of grade 410 need to be oil-quenched. Tempering, to enhance the mechanical properties and hardness of grade 410 steels, follows this process. It is not recommended to perform tempering at temperatures from 400 to 580 °C.

In Which Fields Is 410SS Typically Applied?

410 Stainless Steel finds its applications across a wide spectrum of industries:

- Aerospace

- Automotive

- Petrochemical Industry

- Medical Equipment

- Construction

- Food Processing

- Firearms

- General Manufacturing

- Oil and Gas

- Cutlery and Tools

What are the Advantages of Using 410SS for Casting?

When it comes to casting, 410 Stainless Steel has several advantages:

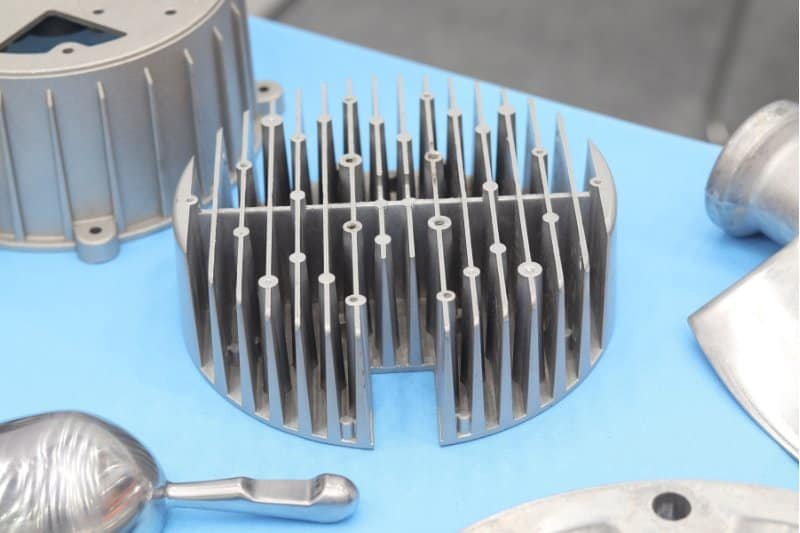

- Moldability: It can be easily molded into complex shapes, making it suitable for intricate components.

- Corrosion Resistance: The chromium content ensures that castings maintain their integrity in corrosive conditions.

- Cost-Effective: 410SS castings are cost-effective due to the relative abundance of the material.

- Durable: Castings made from 410SS are known for their longevity and resistance to wear and tear.

Where is 410SS Casting Commonly Used?

410SS castings find applications in various industries, including:

- Valve and Pump Components

- Marine Equipment

- Downhole tools for oil and gas operations

What is the Heat Treatment Process for 410SS Castings?

To optimize the properties of 410SS castings, a heat treatment process is commonly employed:

- Annealing: Castings are heated to a specific temperature and then slowly cooled. This relieves stress and improves machinability.

- Hardening: Castings are heated to a high temperature and then rapidly quenched in oil or water to achieve maximum hardness.

- Tempering: After hardening, tempering is done to reduce brittleness and enhance toughness.

What Surface Finishes are Achievable with 410SS Castings?

410SS castings can be finished to meet specific aesthetic and functional requirements. Common surface finishes include:

- Polishing: High-quality polishing can provide a mirror-like finish for decorative applications.

- Shot Blasting: This process imparts a textured, matte finish, often used for non-slip surfaces.

- Passivation: Chemical passivation enhances corrosion resistance by removing surface contaminants.

Are There Limitations to Using 410SS for Casting?

While 410SS offers numerous advantages, it’s essential to consider its limitations:

- Limited Heat Resistance: It’s not suitable for applications exposed to extremely high temperatures.

- Not Ideal for Highly Acidic Environments: In strongly acidic conditions, 410SS may corrode.

- Brittleness: In some cases, excessive hardness can lead to brittleness, so proper heat treatment is crucial.

Can 410SS Castings be Customized?

Yes, 410SS castings can be customized to meet specific project requirements. Customization options include varying alloy composition, casting methods, and surface finish to achieve desired performance characteristics.

What Are Some Common 410 Stainless Steel Casting Components?

410 stainless steel casting components are widely used across industries. In automotive applications, we find wheel spacers, valve covers, intake flanges, and dipsticks. Aerospace relies on exhaust manifolds, impellers, pipe fittings, and valve bodies. Medical settings utilize 410 stainless steel for precision components and sensor power supply housings.

Motorcycles benefit from triple clamps, billet wheels, wheel hubs, radiator guards, and brake pedals. Trailers incorporate couplers, hitch balls, pintle hooks, and channel brackets. Bicycles feature 410 stainless steel in bike stems, hubs, and pedals. Kart components include wheel hubs, bearings, steering wheels, and rims. This versatile material ensures durability, strength, and precision across diverse applications.

Conclusion

410 Stainless Steel (410SS) is a remarkable material with a wide array of applications. Its unique combination of properties, including corrosion resistance, hardness, and machinability, make it a sought-after choice in various industries. Whether you’re in the automotive, aerospace, or petrochemical sector, understanding the versatility of 410SS can aid in making informed material choices for your projects.

By providing this comprehensive guide, we aim to position ourselves as a valuable resource for anyone seeking in-depth information about 410 Stainless Steel and its applications. If you have further questions or require customized solutions, feel free to contact us. Explore the possibilities of 410SS castings and unlock the potential for your next project.