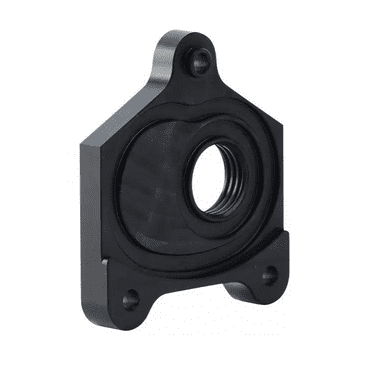

Online CNC Machining Service

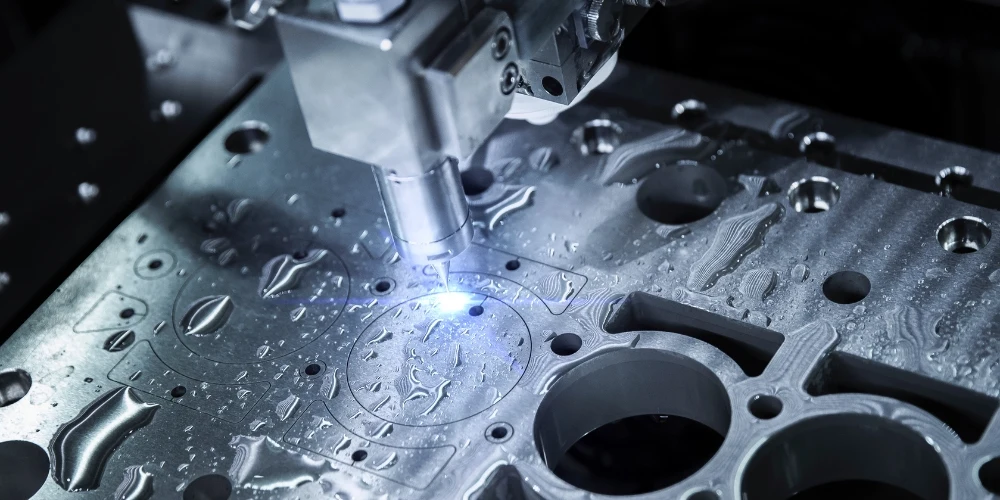

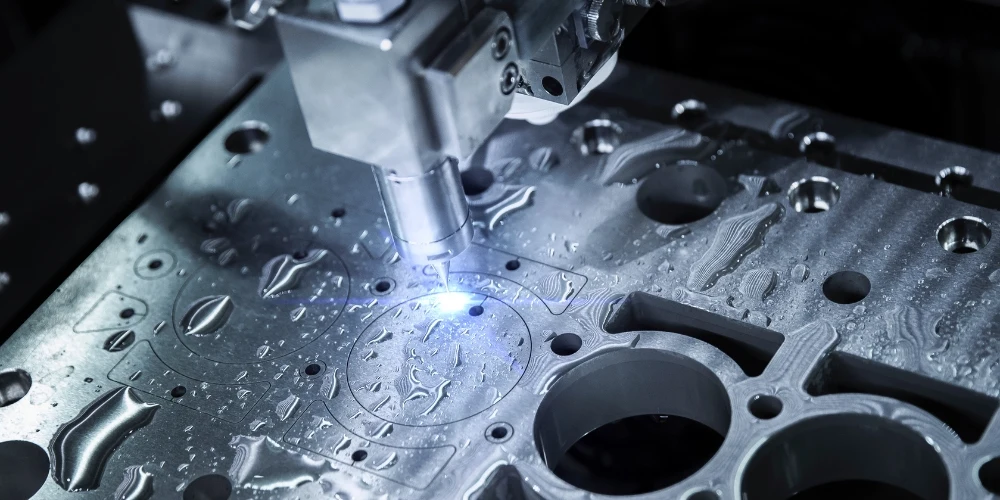

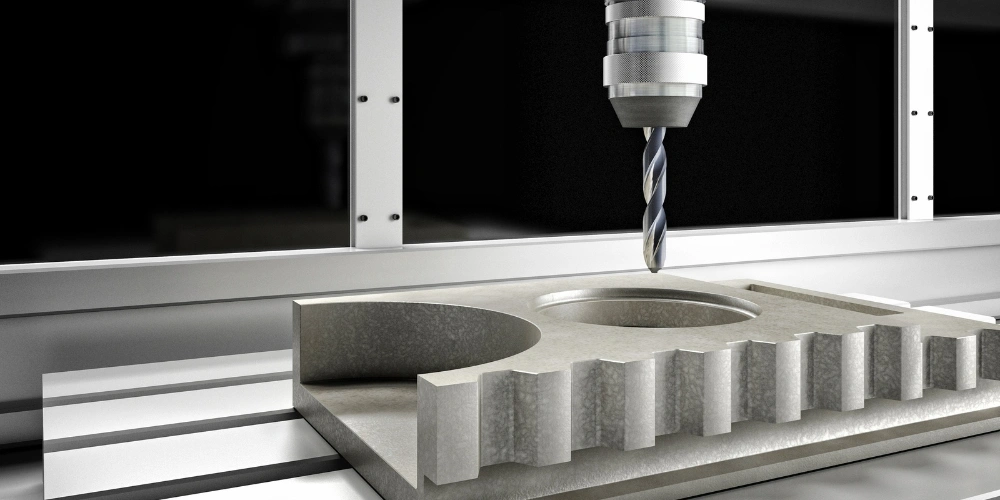

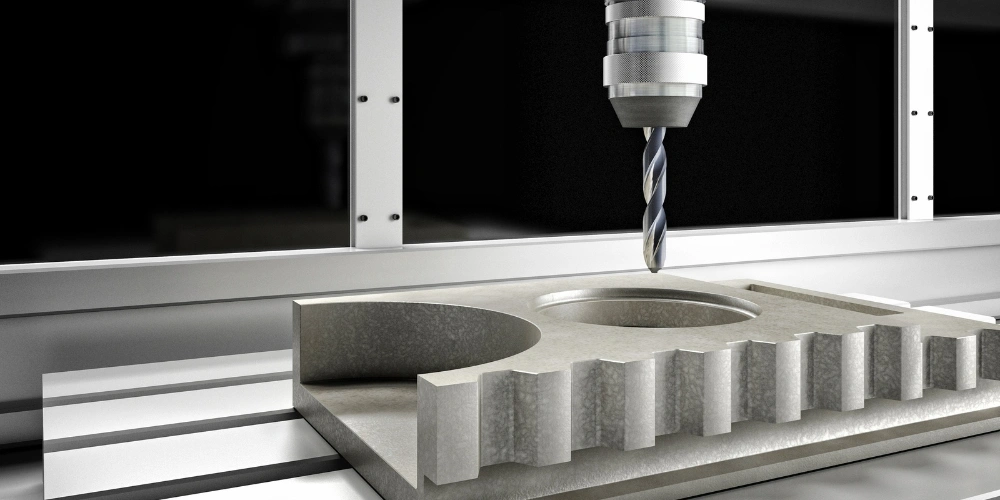

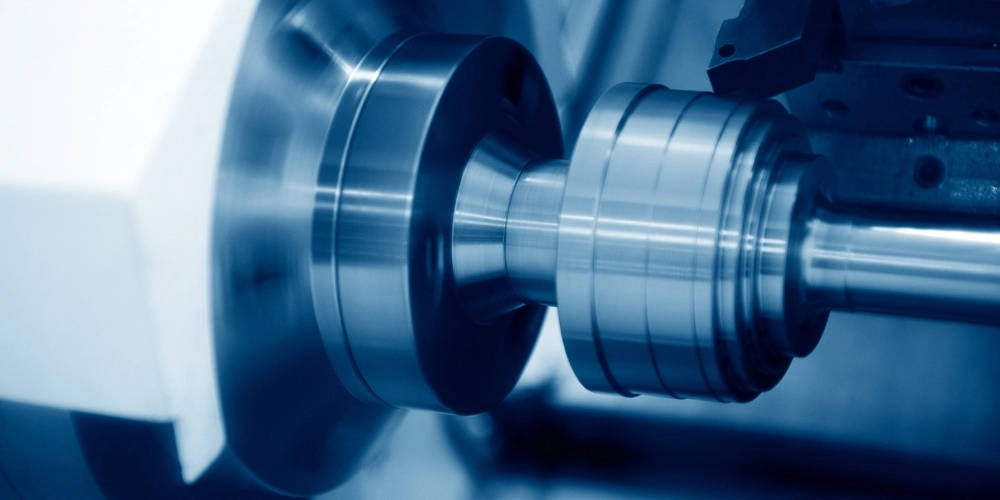

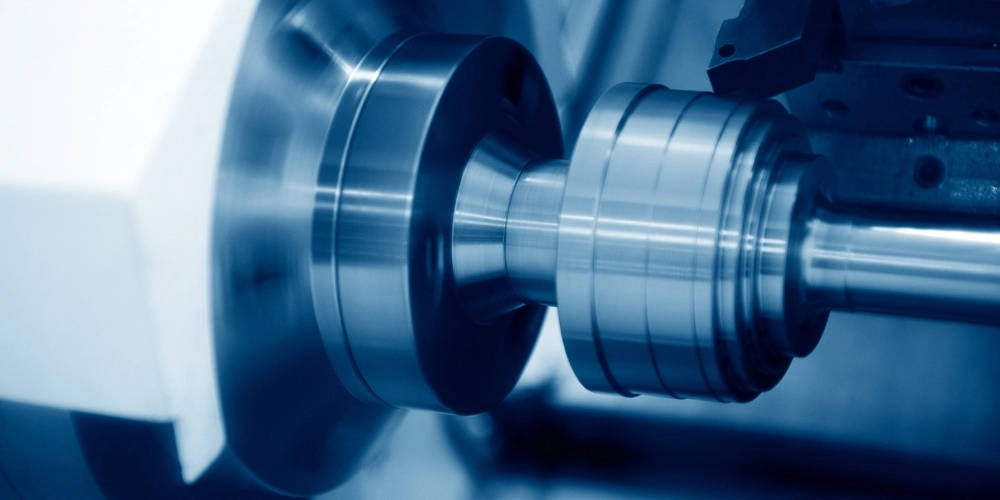

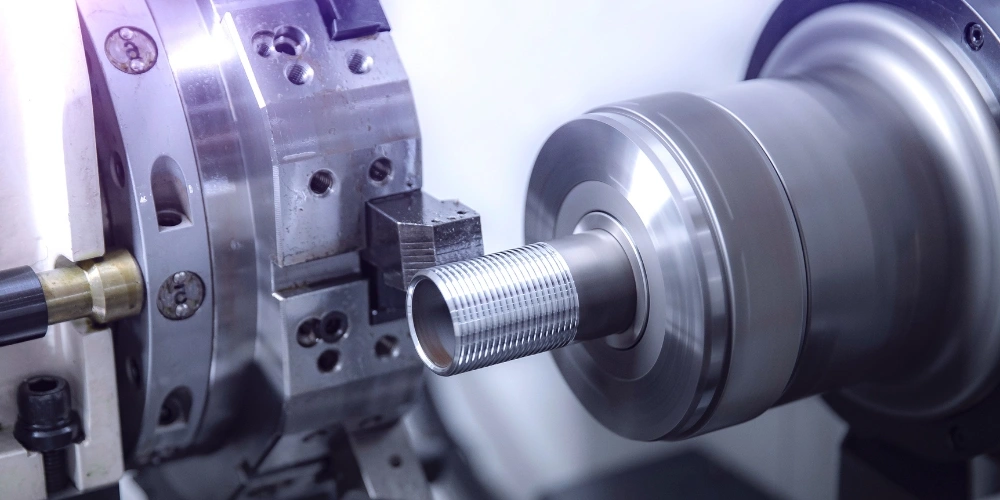

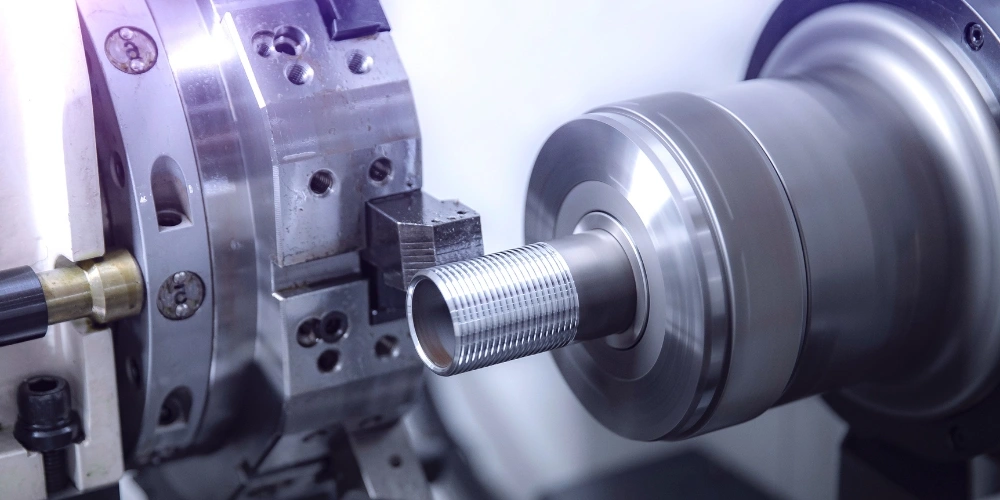

Computer Numerical Control Machining, or simply CNC machining is well known producing procedure that utilizes an automatic fast-moving cutting device to shape raw material, whether it be plastic or metal. CNC machining services cover lathes, milling machining, multi-axis machining, etc. The machine’s tool movements may vary depending on the CNC part, which means the material may keep in place during the tool’s movement, it can also be the toll will not move during the part’s revolvement. It may also happen that they both move at the same time.

The component’s detailed configuration instruction is prepared by the Computer-Aided Design paradigm. This machine can cut and manufacture nearly every metal and plastic material with exceptional preciseness and replicability.

HDC Online CNC Machining Service

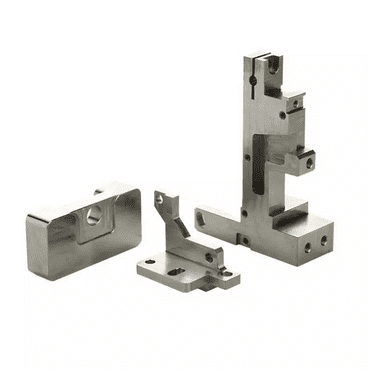

HDC offers CNC machining services on numerous metal and plastic materials. We are ensuring engineering-approved materials in making the most reliable and durable components. Metal parts in HDC are made in stainless steel, aluminum, carbon steel, steel, titanium, etc. We also offer plastic parts wherein your preferred material can be applied in various applications, we have nylon, Delrin, acrylic, polycarbonate, HDPE, PTFE, and so much more.

In the online CNC machining services of HDC, clients don’t have to demand a quote through email, they can just simply upload the file of design/s of their expected component. Then, our advanced virtual quoting program will analyze your component’s requirements and give the actual price of the part, lead time, and full-scale design for manufacturing feedback.

Regardless if you are in need of custom parts with extremely intricate geometries and acquire end-use components immediately, HDC is capable and diligent to come through all of the products and clients’ demands.

We offer various surface finishes that can be an advantage to your product’s capability and longevity. HDC has anodizing, powder coating, heat treating, passivating, brushing, engraving, tumbling, polishing, plating, etc.

Get your most reliable and advanced plastic and metal parts in HDC. We are always up to giving you a quote within 24 hours.

Why choose HDC?

If you are looking for a CNC machining service supplier that is experienced and skillful, has endless capability, gives quality assurance, and provides exceptional customer care, HDC is the one that you need.

HDC provides small and large-volume production machining, as well as rapid prototyping, milling, turning, 3,4,5 axis CNC machining, etc. We machine custom components for every kind of industry, such as automotive, medical, architectural, construction, motocross, and many more.

We are ensuring that your custom parts will get to be made according to your own design and specifications. You may also choose your preferred product material with the help of our professionals, regardless if it is metal or plastic material in any grade.

HDC is an ISO9001 and IATF 16949:2016 certified manufacturer that can manufacture components that is suitable for every kind of application. You are welcome to send us the most intricate designs as we always develop and innovate our ways to create components that will surely satisfy your needs even after many years of usage.

We offer different ways of payment methods like Paypal, T/T, and L/C. We also have shipping ways that can surely make your products arrive at your front door no matter where you are, such as courier, sea shipping, and air shipping. Trade terms are also available in HDC, we have FOB, CFR, and DDP.

Frequently Asked Questions (FAQ) – Online CNC Machining Service

Welcome to our Online CNC Machining Service FAQ, your comprehensive guide to the world of precision metal components crafted with cutting-edge technology. Explore the advantages, working process, materials, technologies, and more as we unveil the seamless fusion of precision and innovation offered by HDC CNC Machining.

What Is an Online CNC Machining Service?

HDC CNC Machining, an Online CNC Machining Service, stands out as a distinguished provider with a 13-year history in OEM metal craftsmanship. Offering quality samples and emphasizing swift delivery, particularly for standard-sized trailer hardware components, we prioritize efficiency and reliability. Our in-house manufacturing facility, staffed by seasoned engineers and a highly skilled design team, sets us apart. HDC excels in various techniques, including CNC processing, sheet metal manipulation, and casting, allowing for extensive customization. With 4-axis and 5-axis CNC machining center, we elevate our capacity to meet intricate project demands. Experience the HDC CNC Machining difference, where precision seamlessly converges with innovation.

What Are the Advantages of Using Online CNC Machining Services?

Opting for Online CNC Machining Services ensures meticulous precision, delivering accurate specifications. The automated process enhances efficiency, meeting diverse deadlines and managing various materials. Cost-effectiveness is achieved through minimized human intervention, reducing material wastage. The technology excels in customization, accommodating intricate designs. Online accessibility adds convenience, allowing seamless design submission and progress monitoring. In summary, these services provide precision, efficiency, versatility, cost-effectiveness, customization, and overall convenience.

What CNC technologies can Online CNC Machining Service providers provide?

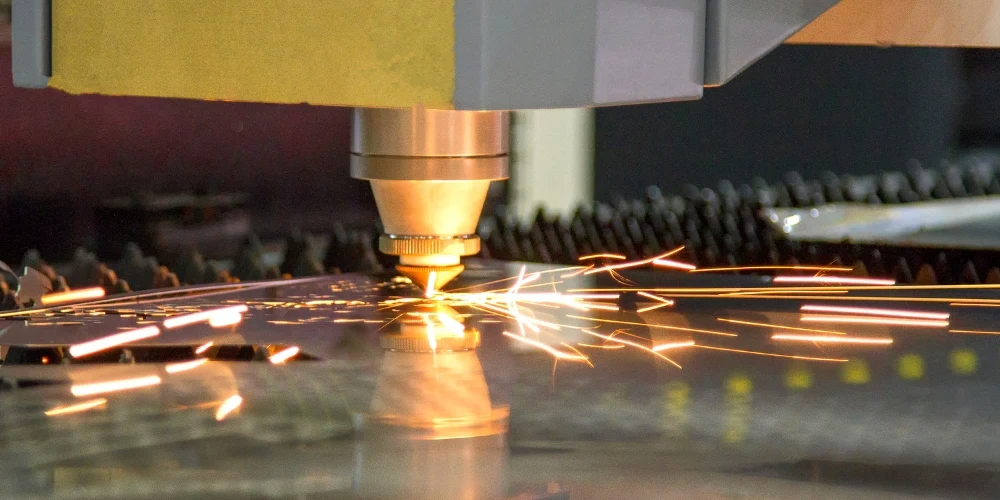

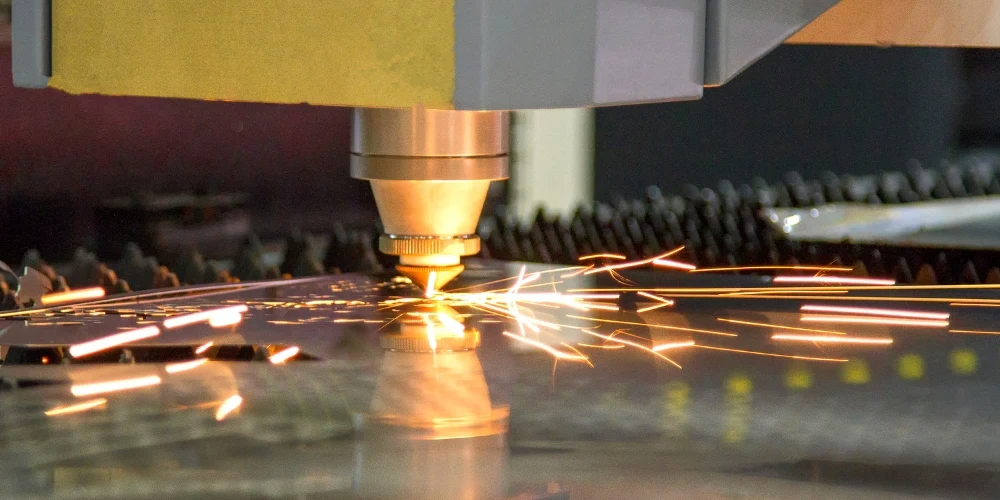

Online CNC machining services offer cutting-edge technologies for diverse manufacturing needs. This includes 3-axis machining for standard tasks, 4-axis precision machining for intricate work, and advanced 5-axis machining for unparalleled flexibility. CNC turning is ideal for cylindrical components, while laser cutting ensures precision in intricate assignments. CNC routing, using a rotating cutting tool, shapes materials with finesse. These technologies guarantee an effective and exacting manufacturing process, proficiently addressing various project specifications.

What Types of Materials Can be Used in Online CNC Machining?

In the realm of online CNC machining, a diverse array of materials caters to varied project needs. In the metallic domain, options like Aluminum, known for its lightness and corrosion resistance, and Steel, esteemed for robustness, offer versatile choices. Brass, a visually appealing alloy, and Titanium, recognized for a high strength-to-weight ratio, are prominent selections. Transitioning to synthetics, ABS exhibits resilience, Polycarbonate offers transparency and fracture resistance, and Nylon combines strength with flexibility. In the organic realm, hardwoods like oak or maple are chosen for both aesthetics and functionality. Modern composites like Carbon Fiber, known for strength and buoyancy, and Fiberglass, a robust plastic composite, find applications in aerospace and sports.

Material selection, guided by factors such as strength, weight, aesthetics, and application, choreographs a bespoke dance, shaping the material landscape for each project’s unique cadence.

What Post-Processing Options Are Available for CNC Machined Parts?

After CNC machining, various post-processing options enhance machined parts. Surface finishing techniques like polishing, brushing, and bead blasting refine aesthetics. Anodizing and powder coating provide protection and color variety. Heat treatment improves material properties, and assembly streamlines component integration. Engraving, deburring, and coatings contribute to safety and longevity. These options are selected based on material, function, and aesthetic goals, offering a customized approach to meet specific project criteria.

What Tolerances Can I Expect from Online CNC Machining?

The tolerances inherent in CNC machining hinge on variables such as material composition, the intricacies of part geometry, and the capabilities of the machining apparatus. Reputable online services disseminate insights into achievable tolerances within their comprehensive documentation. Articulating precise tolerance requisites for your project assumes paramount importance.

Is Online CNC Machining Suitable for Prototyping?

Online CNC Machining distinguishes itself in the realm of prototyping, demonstrating exceptional precision and versatility across a spectrum of materials, including metals, plastics, and composites. Its expeditious nature and exactitude make it an optimal choice for crafting prototypes that closely emulate the final product. The online dimension introduces convenience, facilitating the submission of designs seamlessly without the need for physical presence, thereby streamlining the prototyping process.

Are Online CNC Machining Services Suitable for Large-Scale Production?

Online CNC Machining Services prove highly adept for extensive manufacturing endeavors, seamlessly combining efficiency, precision, and scalability. The automated procedural framework ensures expeditious turnaround times, adeptly addressing the demands of extensive production requirements in a timely manner. The streamlined online accessibility significantly refines communication channels and order management, thereby elevating the overall operational efficiency within expansive manufacturing operations.

How Can I Ensure the Quality of Components from an Online CNC Machining Service?

Ensuring the excellence of components from an Online CNC Machining Service necessitates a thorough examination of certifications such as ISO standards and the procurement of sample components for a firsthand evaluation. Delve into the intricacies of quality control processes, engage in a close collaboration regarding design specifications, and uphold consistent communication to promptly address any arising concerns.

Conclusion

Appreciate your deep dive into the nuances of Online CNC Machining Services with us. Whether you’re in pursuit of intricate prototypes or orchestrating extensive production, HDC CNC Machining is poised to meet the distinctive requirements of your projects. Rely on our proficiency for outstanding components, timely delivery, and a seamlessly orchestrated online interface. Entrust your projects to HDC CNC Machining, where precision and innovation intersect, propelling your endeavors to unprecedented heights.

[toc]