- Home

- 12L14 Carbon Steel: Chemical Composition, Properties, Processing Methods, and Application Fields

12L14 Carbon Steel: Chemical Composition, Properties, Processing Methods, and Application Fields

- Walter

Why Choos HDC to Custom 12L14 Carbon Steel Products

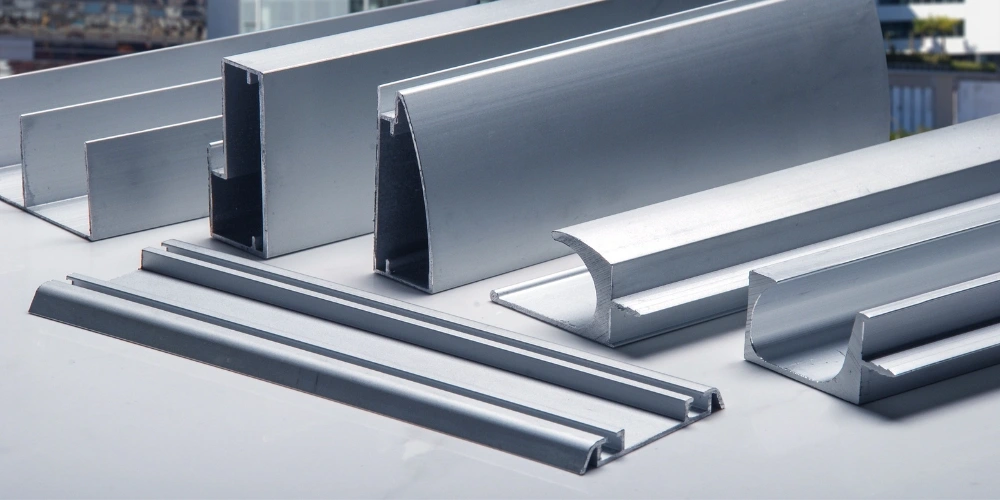

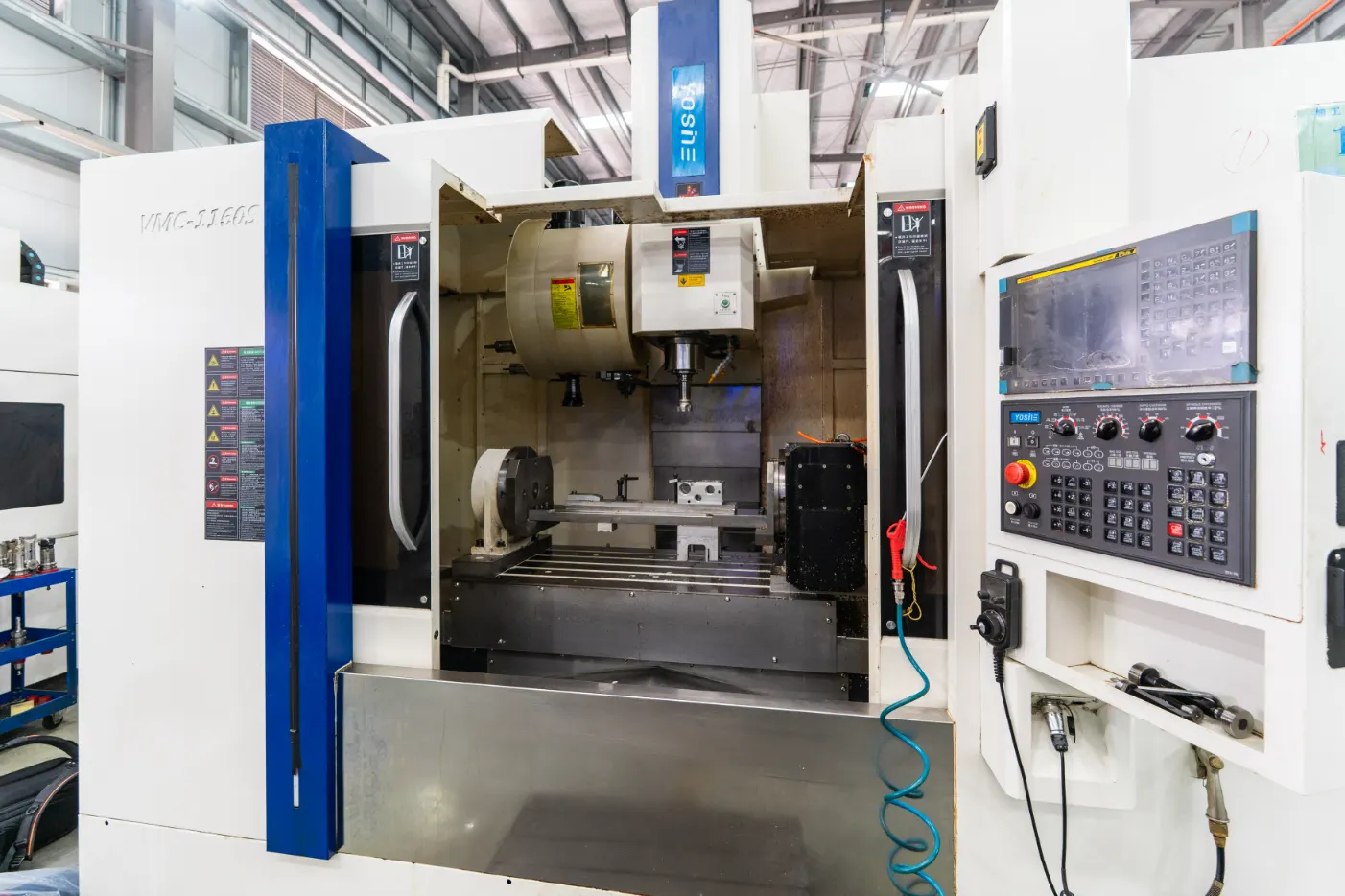

HDC has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your 12L14 carbon steel material components to perfection, tailored to your specific requirements.

Amidst the realm of 12L14 Carbon Steel, our adeptness ensures the production of exacting and superior components. Recognized for its extraordinary workability, 12L14 stands as the optimal selection for intricate designs. The seasoned team at HDC adeptly optimizes machining parameters, guaranteeing faultless dimensional precision and a flawless surface finish. Whether your project involves intricate threading, precise contouring, or meticulous milling, we pledge efficiency and a standard of excellence.

Going beyond the realm of machining, HDC distinguishes itself in comprehending the distinctive attributes of 12L14 Carbon Steel. This specialized knowledge steers our cooperative design process, imparting invaluable insights and guaranteeing that our components not only meet but surpass industry benchmarks. With HDC, anticipate 12L14 Carbon Steel components meticulously fashioned with precision, durability, and an attentive focus on detail—accommodating and exceeding the stipulations of your project.

Overview

12L14 is a free-cutting steel alloy known for its excellent machinability. 12L14 carbon steel is a popular choice for applications that demand exceptional machinability and precision. Its composition, featuring added sulfur and phosphorus, facilitates efficient machining, making it a valuable material for the production of small, intricate components across various industries.

What is Carbon Steel?

Carbon steel is a steel with iron and carbon as the most viable, while other elements are at lower quantity. Carbon steel with mean carbon content, i.e from 0.05% to 2.0%, is produced according to the grade and the application. Carbon steel is regarded for its strength, hardness, and long-term endurance, which makes it to be widely used in different industries like construction, manufacturing, automobile, and infrastructure. The steel is divided into four types based on its carbon content and characteristics, such as low carbon steel (mild steel), medium carbon steel, and high carbon steel. Besides the fact that carbon steel can be further alloyed (mixed) with elements such as manganese, silicon, and sulfur to improve certain attributes like strength, ductility and machinability. Since it is one of the strongest and most affordable types of steel used in the manufacture of parts, components, machinery parts, pipes, and auto frames and other applications.

What Are the Characteristics of 12L14 Carbon Steel?

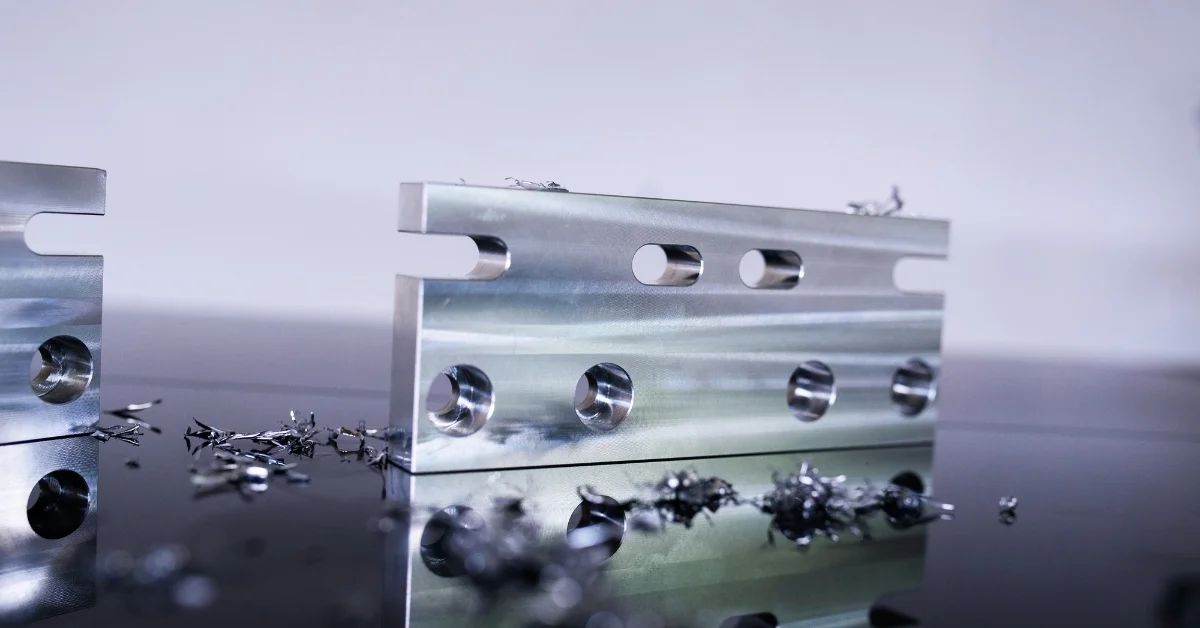

12L14 known as a high-sulfur and lead containing steel is famous for its high machinability. This addition of manganese sulfides to the standard Fe grade composition will give chip breaker characteristics during the metal cutting process and reduce the wear of the cutter drastically to produce excellent surface finish in the machined parts. This steel is not as strong as some other carbon steels but still provides excellent strength as well as ductility for use in different stainless steel applications. With the compliance to the conventional procedures it can be welded, but some precautions are required, as the element is sulfur and lead containing. This steel is cost-effective and is known for its wide use in automotive components, bushings, fittings, and fasteners. Therefore its demands are high due to the precise machining and high production capabilities.

What Is the Naming Basis for 12L14 Carbon Steel?

The naming basis for 12L14 carbon steel is derived from its composition and conformation to the standardization in AISI (American iron and steel institute) system. The “12” in 12L14 is for the average carbon content, approximately 0.12%. The ′L′ indicates that the other element which is lead is there in the alloy. To sum up, the “14” figures shows the sulphur approximately 0.14%. A numerical designation that is alpha-numeric in nature offers a standardized method of identifying and categorizing carbon steels based on their composition and properties. This enables communication and understanding to be improved amongst the industry players.

Chemical Composition of 12L14 Carbon Steel

Element | Content (%) |

Iron, Fe | 97.91 – 98.7 |

Manganese, Mn | 0.85 – 1.15 |

Sulfur, S | 0.260 – 0.35 |

Lead, Pb | 0.15 – 0.35 |

Carbon, C | 0.15 |

Phosphorous, P | 0.040 – 0.090 |

The Influence of the Composition of 12L14 Carbon Steel on Its Properties

Carbon steel that is 12L14 is widely used as base material because it can be used in variety of applications. It contains around 0.12 %, of the carbon that imparts strength and hardness to it, yet retains its moldability. Manganese contributes to the hardenability and strength of steel, while sulfur, about 0.15%, improves machinability by forming manganese sulfides reducing the production costs and prolonging service life of any tools. Lead is also added to further enhance machinability through acting as the lubricant, thus it is able to reduce friction between the cutting tool and the work piece. The composition of 12L14 is precisely controlled to yield outstanding machinability characteristics making it perfect for machining oriented applications in industry where precision is premium and production volumes are high thus suitable for automotive components and fasteners.

Physical Properties of 12L14 Carbon Steel

Properties | Metric | Imperial |

Density | 7.87 g/cm3 | 0.284 lb/in³ |

Mechanical Properties of 12L14 Carbon Steel

Properties | Metric | Imperial |

12L14 Steel Tensile strength | 540 MPa | 78300 psi |

Yield strength | 415 MPa | 60200 psi |

Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

Shear modulus (typical for steel) | 80.0 GPa | 11600 ksi |

Elastic modulus | 190-210 GPa | 27557-30458 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Elongation at break | 10% | 10% |

Reduction of area | 35% | 35% |

Hardness, Brinell | 163 | 163 |

Hardness, Knoop (converted from Brinell hardness) | 184 | 184 |

Hardness, Rockwell B (converted from Brinell hardness) | 84 | 84 |

Hardness, Vickers (converted from Brinell hardness) | 170 | 170 |

Machinability (based on 100 machinability for AISI 1212 steel) | 160 | 160 |

Thermal Properties of 12L14 Carbon Steel

Properties | Metric | Imperial |

Thermal expansion co-efficient (@ 20°C/68°F, typical steel) | 11.5 µm/m°C | 6.39 µin/in°F |

Thermal conductivity (typical steel) | 51.9 W/mK | 360 BTU in/hr.ft².°F |

Equivalent Materials of 12L14 Carbon Steel

UNS number | G12144 |

US name | AISI 12L14, 12L13, 12L15 to ASTM A29, ASTM A510, ASTM A519, ASTM A576, SAE J403 |

EN name | 11SMnPb37, 11SMnPb30, 9SMnPb28 to BS EN 10087, BS EN 10277; S300Pb to NF A35 561 |

EN number | 1.0737, 1.0718, 1.9718 |

JIS (Japanese) name | SUM24L to JIS G4804 |

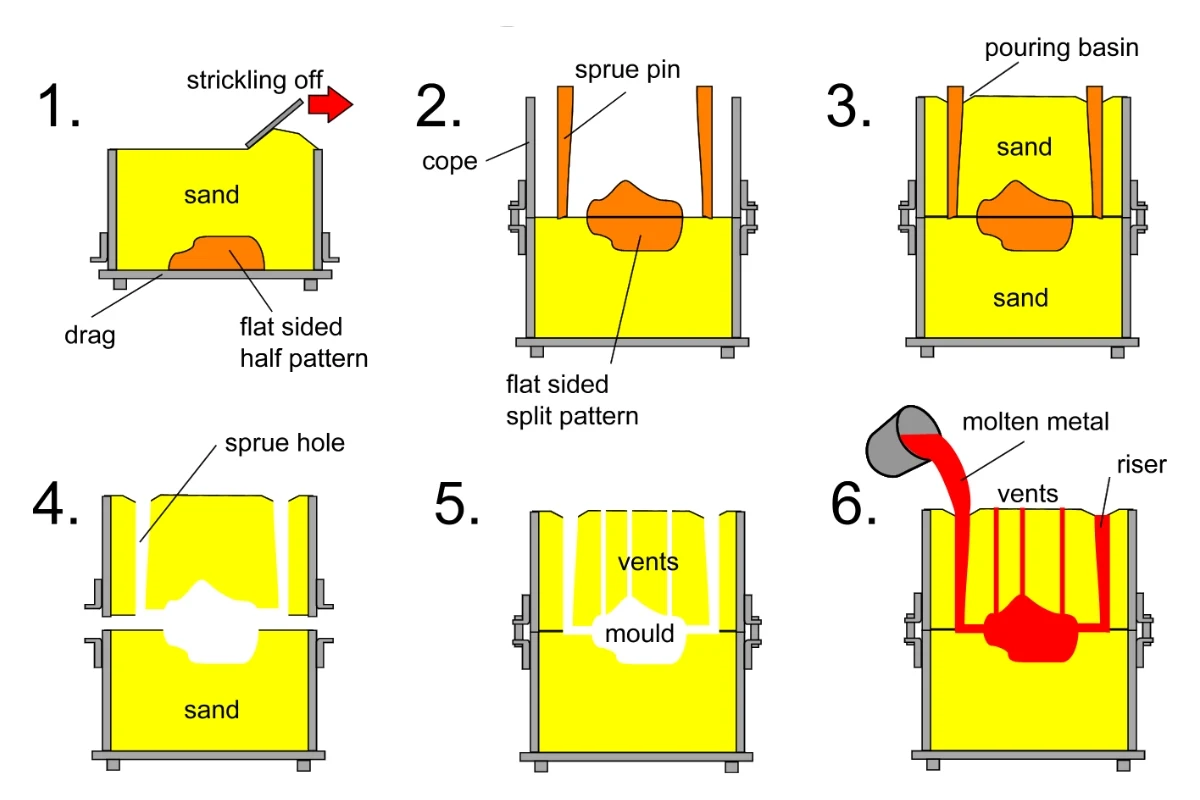

Which Processing Methods Are Suitable for 12L14 Carbon Steel?

12L14 steels are highly versatile in manufacturing because they machine well with ease and have moderate strength. Especially, it mainly masters substantial operations including turning, milling, drilling, and threading thanks to its lead and sulfur richness which can chop chips and decrease tool wear. Furthermore, it further can be formed by cold forming processes as for example bending and stamping without preheat and annealing. However, efforts must be made to avoid it due it its relatively higher sulfur and lead content. Heat treatment processes, which are used to alter properties, are usually the exception since 12L14 is rarely hardened by this process. Overall, 12L14 carbon steel is the material of choice where high precision in machining is required and strength is also a critical factor.

What Are the Limitations of 12L14 Carbon Steel?

The extremely precision of machinability plus the moderate strength make 12L14 carbon steel have some limitations. Carbon steel, which is characterized by comparatively low strength and toughness, is not very suitable for applications demanding high strength or wear resistance. Furthermore, the sulphur that is useful for machinability may cause the metal to become brittle, which may result into such problems as cracking. Weldability is dealt with due to its sulfur and lead content which is higher than the usual, as it requires some particular techniques in order not to cause weld cracking and/ or poor quality. In addition, 12L14 steel has very limited heat treatability and the use of additional protection measures is needed to mitigate corrosion in some special environments. In that way, the main advantages of this technology for machining component parts should be weighed up against its limitations for materials selection.